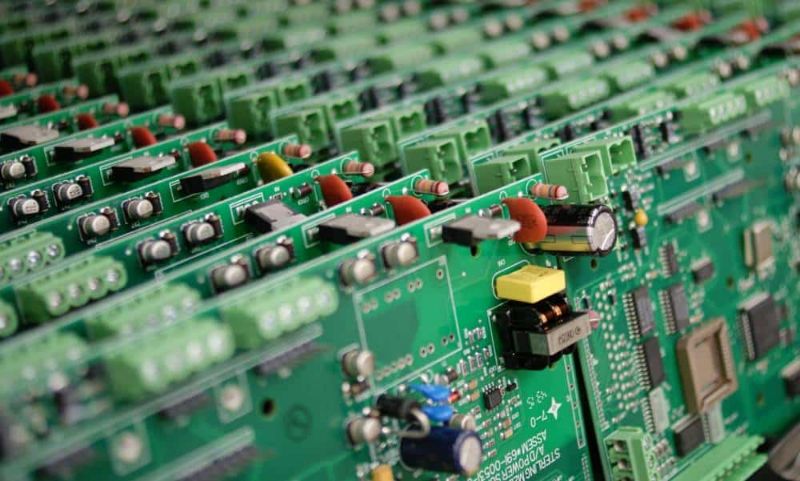

In a world propelled by innovation, Printed Circuit Boards (PCBs) have emerged as the unsung heroes powering our devices. From the smartphone in your pocket to the intricacies of medical equipment, PCBs are the lifeblood of modern technology. But how these intricate circuitry marvels come to life is an art in itself. This is where the concept of outsourcing PCB design takes center stage. In today’s landscape, where time is of the essence, and innovation is the currency of competitiveness, the decision to outsourcing your PCB design is strategic. It’s a move that transcends traditional approaches, harnessing the expertise of Electronics Manufacturing Services (EMS) providers to bring your concepts to fruition.

Understanding PCB suppliers (EMS)

Defining PCB suppliers (EMS)

Before delving into the reasons to outsource PCB design, it’s crucial to understand the role of Electronics Manufacturing Services (EMS) providers. These entities specialize in the end-to-end creation of electronic products, encompassing everything from design and prototyping to PCB manufacturing and assembly. By collaborating with a reputable EMS provider, you’re tapping into a comprehensive solution ensuring the seamless transition from concept to finished product.

Who Needs a PCB Supplier?

The need for a PCB supplier isn’t confined to a specific niche; it spans industries and businesses of varying sizes. Start-ups aiming to bring innovative products to the market, mid-sized companies aiming to streamline operations, and large enterprises seeking cost-efficient solutions can benefit from partnering with a reputable circuit board manufacturer. From consumer electronics to automotive manufacturers, aerospace entities to medical device creators, the demand for reliable and efficient PCB design and Pcb manufacturing is universal.

Why Partner with a PCB supplier?

Partnering with a PCB supplier extends far beyond the convenience of outsourcing. It’s a strategic move that aligns with contemporary business dynamics. The outsourcing approach allows you to focus on your core competencies while entrusting the intricate PCB layout and assembly process to experts. This ensures that your design adheres to industry standards and grants you access to state-of-the-art technology and PCB manufacturing processes. By partnering with a reputable circuit board manufacturer, you’re essentially gaining a competitive edge through quality, efficiency, and innovation.

What do PCB Design Services Provide?

PCB design services offer a comprehensive suite of expertise and resources that go beyond mere circuitry layouts. These services encompass a wide range of activities and deliverables, ensuring that your PCB design journey is not only efficient but also fruitful.

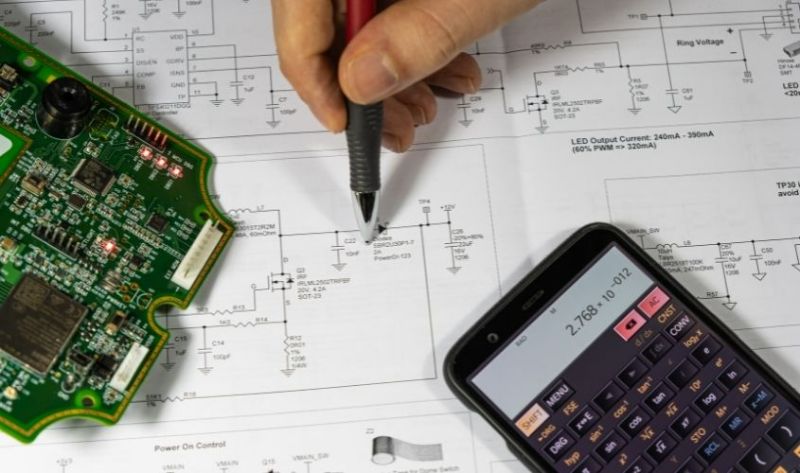

Schematic Design

The foundation of any PCB design is the schematic—a visual representation of the circuit’s components and their connections. PCB design services provide meticulous schematic design, ensuring that every element is accurately represented before moving on to the physical layout.

Component Selection and Footprint Creation

Selecting the right components for your design is critical. PCB design services assist in choosing components that meet your project’s requirements, considering factors like functionality, cost, and availability. They also create accurate footprints for these components, ensuring seamless integration into the layout.

PCB Layout and Routing

The heart of PCB design lies in its layout. PCB design services excel in translating schematic diagrams into physical layouts, optimizing component placement for minimal signal interference and efficient routing. Their expertise ensures that critical design considerations such as trace length matching, impedance control, and signal integrity are upheld.

Design Rule Checks (DRC)

To ensure the accuracy and manufacturability of the design, PCB design services conduct thorough design rule checks. These checks identify potential errors, such as spacing violations, incorrect clearances, or unconnected nets. Addressing these issues at an early stage prevents costly revisions during manufacturing.

Gerber File Generation

PCB manufacturing relies on Gerber files—a standard file format that contains all the information needed for manufacturing the board. PCB design services generate accurate Gerber files, encompassing layers, copper traces, solder masks, and more. These files act as the blueprint for the fabrication process.

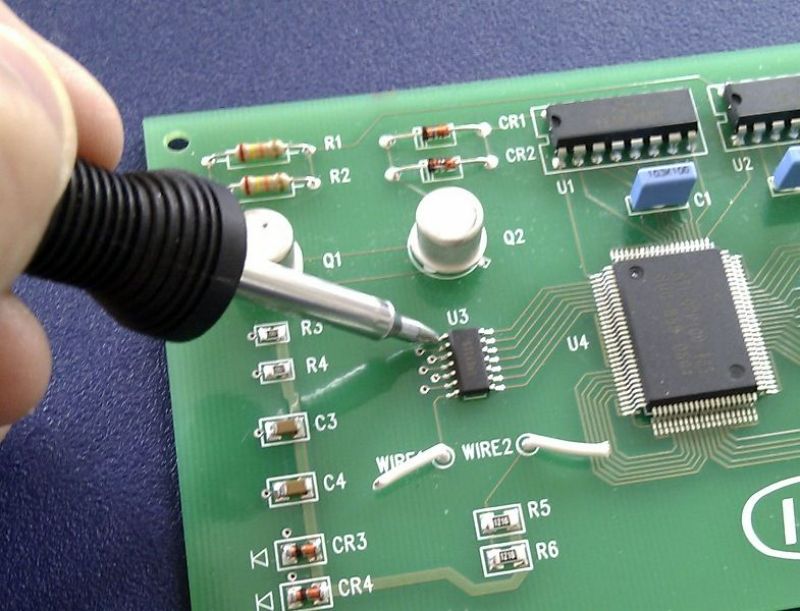

Prototyping Support

Prototyping is a crucial step to validate the design before mass production. PCB design services provide support during the prototyping phase, assisting in troubleshooting and refining the design based on real-world testing results.

Collaboration with Manufacturers

Smooth collaboration between designers and PCB manufacturers is pivotal. PCB design services facilitate this collaboration, ensuring that design intent is effectively communicated to the manufacturing team. This collaboration streamlines the transition from design to production and minimizes potential discrepancies.

Design Documentation

Comprehensive documentation is essential for future reference, troubleshooting, and modifications. PCB design services provide detailed design documentation, including schematic diagrams, bill of materials (BOM), assembly drawings, and design notes.

Design Iteration and Optimization

Design refinement is an iterative process. PCB design services assist in optimizing the design based on testing and feedback, ensuring that the final product meets all functional, performance, and reliability requirements.

Stay Updated with Industry Trends

The field of electronics is ever-evolving, with new technologies, standards, and regulations emerging regularly. PCB design services stay updated with these trends, ensuring your design remains relevant and competitive.

10 Reasons to Outsourcing Your PCB design

Expertise and Experience

Outsourcing your PCB design brings a team of seasoned professionals to the table, individuals who have navigated the complexities of designing circuit boards across various industries. These experts bring a wealth of experience and specialized knowledge in areas such as signal integrity, thermal management, and component placement. By tapping into their expertise, you’re not only ensuring that your design meets functional requirements but also that it adheres to industry best practices, resulting in a robust, reliable, and high-performance PCB.

Reduced PCB costs and Overheads

The allure of in-house design teams is often overshadowed by hidden PCB costs, including recruitment, training, and maintaining a design infrastructure. Outsourcing PCB design alleviates these financial burdens by offering access to expert designers without the need for extensive hiring and training efforts. This approach translates to PCB cost savings that can be redirected to other critical aspects of your project, all while delivering high-quality designs that align with your vision.

Faster Time-to-Market

In the fiercely competitive landscape of product development, time-to-market can make all the difference between success and obscurity. Outsourcing accelerates the design process by introducing a team of experts who are well-versed in the intricacies of PCB design. Their collective experience ensures that your design cycle is streamlined, reducing the time it takes to move from concept to market-ready product. This agility not only gives you a competitive edge but also maximizes the window of opportunity for your product.

Access to Advanced Tools and Technology

Staying at the forefront of technology requires continuous investment in tools and software. Outsourcing your PCB design provides access to a toolbox of cutting-edge design tools and technology. These tools, often expensive to acquire and maintain in-house, empower designers to incorporate the latest trends and features into your designs. The result is a PCB that not only meets current industry standards but also embraces emerging technologies that can set your product apart.

Scalability and Resource Management

Navigating the peaks and valleys of project demands requires a versatile approach to resource allocation. Outsourcing PCB design offers the flexibility to scale resources according to project requirements. During peak periods, you can seamlessly tap into the expertise of the extended team, ensuring that your project remains on track without resource shortages.

Risk Mitigation and Quality Assurance

Outsourcing your PCB design is akin to distributing the responsibility for design success. Seasoned professionals, backed by a wealth of experience, are adept at navigating potential pitfalls. They possess a keen eye for spotting potential design flaws and take preemptive measures to mitigate risks. With stringent quality assurance protocols, an outsourced team ensures that your design adheres to industry standards and best practices, resulting in a final product that’s not only functional but also reliable.

Innovation and Collaboration

By entrusting your PCB design to a dedicated team, you’re freeing up internal resources for the true essence of innovation. Collaborative ideation between your business and your outsourcing partner can lead to breakthroughs in design, functionality, and efficiency. The external perspective often brings fresh insights that might not have been considered otherwise. This collaboration accelerates the ideation process and can significantly influence the final design in ways that align with your objectives.

Global Reach and Specialized Services

Outsourcing knows no geographical boundaries. When you opt to partner with an EMS provider for your PCB design, you’re gaining access to a global network of specialized services. Whether it’s harnessing a specific expertise, accessing state-of-the-art manufacturing equipment, or collaborating with experts on a different continent, the global reach of outsourcing expands your horizons exponentially.

Supply Chain Management and Collaboration

The process of designing a PCB doesn’t halt at the schematic and layout stages; it extends to the manufacturing floor. An effective partnership with an EMS provider streamlines the interaction between design and manufacturing, resulting in a seamless handoff. Collaborative discussions about design considerations with the manufacturer ensure that your design aligns with manufacturability principles, reducing lead times and avoiding costly rework.

Focus on Core Competencies

Outsourcing your PCB design allows your business to play to its strengths. It’s an acknowledgment that while PCB design is crucial, it might not be the core focus of your enterprise. By delegating this task to experts, you can devote your internal resources to the areas that truly set you apart. This strategic move bolsters your overall efficiency, optimizes resource allocation, and paves the way for sustainable growth.

Conclusion

This comprehensive exploration of the benefits and reasons behind outsourcing your PCB design shows that this strategic move is more than just a trend—it’s a path to efficiency, innovation, and growth. By partnering with Electronics Manufacturing Services (EMS) providers, you’re gaining access to a wealth of expertise, advanced technologies, and efficient processes.

Outsourcing your PCB design allows you to harness the collective strength of experienced professionals, leading to optimized designs, reduced PCB cost, and accelerated time-to-market. The ability to focus on your core competencies and collaborate on a global scale amplifies your competitive edge.

As the electronics industry continues to evolve, the role of outsourced PCB design becomes even more pivotal. It’s a smart move that positions your business for success in an ever-changing landscape. So, as you consider your next PCB design project, remember the 10 reasons and countless benefits of outsourcing—it’s not just a strategic choice, it’s a leap towards a brighter technological future.