Reliable PCB Assembly Services for Your Electronics Manufacturing Needs

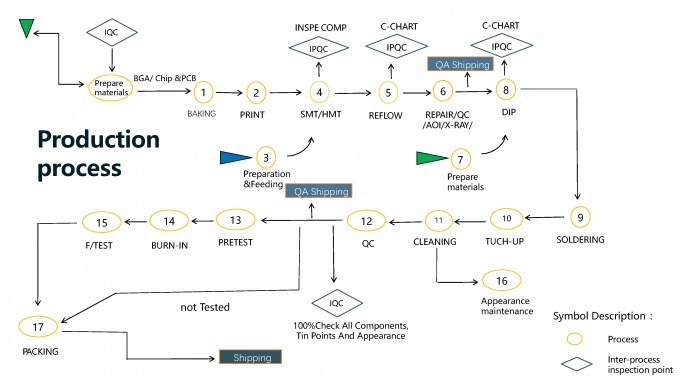

From prototype to high-volume production, we offer precision assembly services, including printed circuit board assembly, with fast turnaround times, competitive pricing, and unwavering quality.

Although we have high-speed pick and place machines, multi-zone reflow ovens, and Electrovert dual wave / chip wave solder machines, the people on the assembly floor are the heart and soul of our operation. Your assemblies are in the hands of the most dedicated and talented team of Program Managers, Process Engineers, Floor Leads, Quality Control Personnel, Kit Auditors, Prototype Technicians, and Touch-up Technicians available.

You will not find a more dedicated group of people than the PCB Assembly team here at PCBLOOP. This is demonstrated by the increasing number of “Thank You” letters we receive from customers, many of which have found a home on the walls of our conference room.

Our cutting-edge assembly equipment allows us to meet all of your PCB board assembly needs under one roof at a reasonable price.

Why Work with Us

1. Cost and Efficiency:

- Implement lean manufacturing

- Utilize advanced automation and robotics

- Offer value engineering

- Establish strategic partnerships with component suppliers

2. Time-to-Market:

- Adopt agile product development methodologies

- Offer rapid prototyping services

- Maintain close collaboration and communication with clients

- Leverage advanced manufacturing technologies

3. Complex Regulatory Compliance:

- Develop a deep understanding of relevant regulations and standards

- Establish robust quality management systems

- Employ certification experts

- Maintain thorough documentation and traceability

4. Intellectual Property Protection:

- Implement strict access controls, confidentiality agreements, and non-disclosure agreements (NDAs)

- Establish secure systems and protocols

- Clearly define and enforce IP protection policies

- Regularly update security measures

5. Supply Chain Management:

- Build strong relationships with trusted suppliers and distributors

- Conduct thorough supplier audits

- Implement supply chain visibility tools and processes

- Develop contingency plans and alternative sourcing strategies

6. Technological Advancements:

- Invest in continuous learning and development programs for employees

- Collaborate with technology partners and research institutions

- Foster an innovative culture within the organization

- Provide technology consulting services to clients

7. Skill Gap:

- Establish training and mentorship programs

- Collaborate with universities and educational institutions

- Engage in industry associations and participate in knowledge-sharing events

- Offer design and manufacturing consulting services to clients

8. Customization and Flexibility:

- Maintain a customer-centric approach

- Offer flexible manufacturing capabilities

- Develop modular design approaches and flexible manufacturing processes

- Foster strong communication channels with clients

Comprehensive PCB Assembly Solutions

- Surface Mount Technology (SMT): High-speed, automated placement of surface mount components for high-volume production.

- Through-Hole Technology (THT): Precise hand insertion and wave soldering for through-hole components.

- Mixed Technology Assembly: Seamless integration of SMT and THT components on a single PCB board assembly.

- Box Build Assembly: Complete product assembly, including enclosure integration, testing, and packaging.

- Cable & Wire Harness Assembly: Custom cable and wire harness assembly to complete your product.

- Conformal Coating: Protection against moisture, dust, and other environmental factors.

- Testing & Inspection: Rigorous quality control and testing throughout the assembly process, including automated optical inspection (AOI), X-ray inspection, and functional testing.

Testing Procedures:

Before the final shipment, the assembled printed circuit boards will be subjected to a variety of tests:- Visual inspection: general quality check.

- Checks for BGAs, QFNs, and bare circuit boards using X-ray inspection.

- Checks for solder paste, 0201 components, missing components, and polarity during AOI testing.

- ICT: In-Circuit Test to check for open and shorts, following your test procedures to validate the basic functions of the product.

ISO Certification:

PCBLOOP’s manufacturing facilities comply with ISO 9001, ISO 13485, IATF 16949, UL, GS, and other standards. Send us your data, and we’ll assemble your PCB for you. We provide high-quality service with quick turnaround times at an affordable price.- Fast turn times

- Small prototype runs

- Medium production runs

- High-Mix Low-Volume (HMLV)

- Low-Mix High-Volume (LMHV)

- Great prices

Typical data needed for quote:

- BOM with part numbers from manufacturers

- Data for all machine-placed parts’ centroid

- PCB Gerber files

- If you supply us with bare boards, please include a solder paste gerber file

- Assembly diagram

Advanced Technology & Expertise

Our state-of-the-art facility is equipped with the latest PCB assembly equipment and technologies. We have a team of highly skilled technicians and engineers dedicated to producing high-quality assemblies. Our capabilities include:

- Component Placement: High-precision placement of components down to 0201 package size.

- Soldering Techniques: Reflow soldering, wave soldering, and selective soldering.

- Inspection & Testing: Automated optical inspection (AOI), X-ray inspection, in-circuit testing (ICT), and more.

Quality You Can Trust

We are committed to delivering the highest quality PCB assemblies. Our rigorous quality control process includes:

- Incoming Component Inspection: Verification of all components to ensure authenticity and quality.

- In-Process Inspection: Monitoring quality throughout the assembly process.

- Final Inspection: Thorough inspection of finished assemblies before shipment.

- Certifications: ISO 9001, ISO 14001, RoHS, IPC-A-610, etc.

Fast Turnaround & Competitive Pricing

We offer competitive pricing and fast turnaround times to meet your project deadlines. Request a quote today to get started on your PCB assembly project!

Testing Procedures

Before the final shipment, the assembled boards will be subjected to a variety of tests:

1. Visual inspection: general quality check.

2. Checks for BGAs, QFNs, and bare circuit boards using X-ray inspection.

3. Checks for solder paste, 0201 components, missing components, and polarity during AOI testing.

4. ICT:In-Circuit Test to check for open and shorts

5. Following your test procedures to validate the basic functions of the product.

ISO Certification

PCBLOOPs manufacturing facilities are in accordance with ISO9001, ISO 13485, IATF 16949, UL, GS, and other standards.

Send us your data and we’ll assemble your PCB for you. We provide high-quality service with quick turnaround times at an affordable price.

Fast turn times

Small prototype runs

Medium production runs

High-Mix Low-Volume (HMLV)

Low-Mix High-Volume(LMHV)

Great prices

Typical data needed for quote

BOM with part numbers from manufacturers

Data for all machine-placed parts’ centroid

PCB Gerber files

If you supply us with bare boards, please include a solder paste gerber file

Assembly diagram

Frequently Asked Questions

We provide a wide range of product design and manufacturing services, including electronic product concept design, hardware circuit design, software development, printed circuit board assembly, exterior and interior structure design, prototype production, mass production, supplier management, procurement services, and sales of specific electronic products. Our goal is to offer a full range of customized solutions based on customer needs.

The cost of product development varies depending on a number of factors, such as the complexity of the design, the number of prototypes required, and the volume of production. We will provide you with a detailed quote once we have a better understanding of your specific requirements related to printed circuit board assembly.

- Our development process typically involves the following steps:

- Requirements gathering: We will work with you to gather your product requirements and develop a detailed product specification.

- Concept design: We will develop a concept design for your product, including schematics and PCB board assembly.

- Prototyping: We will build a prototype of your product to test its functionality and performance.

- Production: Once you are satisfied with the prototype, we will move into production and manufacture your product.

Yes, we provide after-sales support and maintenance services for our PCB assembly services. Once your product is delivered, we will continue to work with you to provide the necessary technical support, troubleshooting, and maintenance services to ensure the normal operation of the product and the satisfaction of your customers.

It is easy to start a project with us. You can contact us through our website or send an email to our customer service team. Please provide the project requirements and detailed description related to your printed circuit Board, and our team will contact you as soon as possible to discuss the project details and develop a cooperation plan.

Agency testing typically takes place after the prototype has been built and a small scale of marketing tests has been done. We will work with you to identify the appropriate testing agencies and ensure that your product meets all applicable regulatory requirements for printed circuit board assembly.

We provide complete documentation for our custom circuit board designs, including schematics, PCB layout files, and a bill of materials, production files, etc.

Yes, we provide rapid prototyping services in terms of bare PCB and PCB assembly. Prototyping is an important step in the development process, as it allows you to test the functionality and performance of your product before moving into production.

Turnaround time depends on the complexity of the board, component availability, and order volume. For prototypes, we can often turn projects around in 10 days. Larger production runs typically require 4 weeks. We provide accurate lead time estimates after reviewing your project details.

We are flexible and can accommodate both low-volume prototypes and high-volume production runs. Contact us to discuss your specific needs.

We accept a variety of file formats, including Gerber files, ODB++, and CAD files (e.g., Eagle, Altium, KiCad). Please provide us with the most complete and up-to-date version of your design files.

Yes, we offer component sourcing services to streamline your supply chain for PCB assembly. We work with a global network of authorized distributors and reputable manufacturers to ensure you get the right parts at the best price. We can also work with components you provide.

We can assemble a wide range of components, including surface mount components (SMD) down to 0201 package size, through-hole components, BGAs, micro-BGAs, and fine-pitch components.

You can request a quote for our PCB assembly services by submitting your design files (Gerber files preferred), bill of materials (BOM), and assembly instructions through our website or by contacting us directly.

We offer a variety of shipping and delivery options for your PCB board assembly needs. We can ship your circuit boards to any location in the world.