In the realm of modern electronics, the pursuit of smaller, faster, and more powerful devices is unceasing. Yet, this pursuit comes with a notable challenge: heat. The heat generated by electronic components can compromise their performance and longevity. This is where PCB thermal management steps in. In this comprehensive guide, we delve into the critical world of PCB Thermal Management Techniques ,that are indispensable for preventing overheating and optimizing device performance.

Understanding PCB Thermal Design

Picture this: a printed circuit board (PCB) is the backbone of electronic systems, and just like our own bodies, maintaining the right temperature is vital. PCB Thermal Design is the art and science of managing heat within electronic systems. The significance of this design aspect cannot be overstated. When components overheat, they become susceptible to failure, reduced efficiency, and even catastrophic malfunctions. PCB Thermal Design is the proactive measure that ensures the optimal operation of electronic devices under varying conditions.

Factors Affecting PCB Thermal Performance

In the intricate world of electronics, where performance and reliability are paramount, the thermal management of Printed Circuit Boards (PCBs) emerges as a critical consideration. The thermal behavior of a PCB is influenced by a combination of factors that collectively dictate how effectively heat is generated, conducted, and dissipated. Understanding these factors is pivotal to designing systems that operate optimally without succumbing to the detrimental effects of overheating. Let’s delve into the key factors that influence PCB thermal performance:

1. Power Dissipation: The Heat Source

At the heart of thermal considerations lies the concept of power dissipation. Electronic components, such as microprocessors, power regulators, and integrated circuits, consume power during operation. A fraction of this power is converted into useful work, while the remainder is dissipated as heat. The rate at which heat is generated depends on the power consumed by each component and the cumulative effect of all components on the PCB. Components that draw higher currents or operate at elevated frequencies tend to generate more heat.

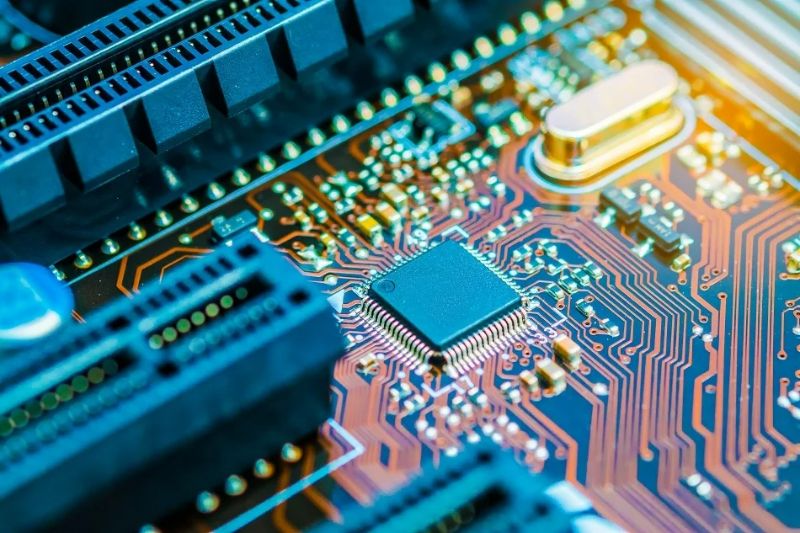

2. Component Density and Arrangement

The arrangement and density of components on a PCB significantly impact the distribution of heat. Compact designs with densely packed components can lead to localized heat buildup, especially when components are in close proximity. Conversely, well-distributed components with sufficient spacing allow heat to disperse more evenly. Designers must consider not only the overall arrangement but also the grouping of components based on their thermal behavior. Heat-generating components should be positioned to optimize heat dissipation while minimizing heat accumulation in sensitive areas.

3. Ambient Temperature and Airflow

The surrounding environment plays a crucial role in the thermal performance of a PCB. The ambient temperature, or the temperature of the surrounding air, affects how efficiently heat is dissipated. Higher ambient temperatures reduce the temperature gradient between the components and the environment, making it more challenging to dissipate heat. Airflow, whether natural or forced, further influences the PCB’s ability to cool down. Adequate ventilation and proper enclosure design can facilitate better airflow, enhancing the overall thermal management strategy.

4. Material Properties and Thermal Conductivity

The materials used in Pcb fabrication have varying thermal conductivities, which dictate their ability to transfer heat. Substrates, laminates, and copper traces all contribute to heat conduction. Selecting materials with higher thermal conductivity enables more efficient heat transfer away from heat-generating components. For instance, materials like metal core PCBs, which have a layer of thermally conductive material beneath the copper layer, enhance heat dissipation by providing a direct heat conduction path.

5. Electrical Currents and Impedance

The electrical currents flowing through traces and components introduce resistance, leading to Joule heating. High current densities can result in localized temperature spikes, impacting both the components’ reliability and the PCB’s overall thermal behavior. Minimizing impedance in traces reduces resistive heating and prevents overheating. Additionally, the impedance of transmission lines can affect signal integrity and thermal behavior, making impedance control an integral part of thermal management.

6. Component Junction Temperature

The temperature at the junction of semiconductor components, often referred to as the junction temperature, is a critical parameter in thermal management. Excessive junction temperatures can lead to performance degradation, reduced lifespan, and even permanent damage to components. Designers must ensure that components are operated within their specified temperature limits to maintain reliable operation and prevent accelerated aging.

Choosing Suitable PCB Materials

Selecting the right materials for your PCB is akin to choosing the right armor for battle. Materials with high thermal conductivity are akin to heat-conducting shields that help dissipate heat effectively. Metal core PCBs, for instance, incorporate a metal layer beneath the PCB’s surface, allowing heat to spread across the metal layer and dissipate. Ceramic substrates possess excellent thermal conductivity and electrical insulation properties, making them ideal for high-power applications. The materials you choose can significantly impact the overall thermal resistance of the PCB.

12 PCB Thermal Management Techniques

Heat Sinks and Heat Spreaders

Think of heat sinks and heat spreaders as the cooling knights of your electronic realm. They work tirelessly to draw heat away from high-power components and distribute it across a larger area, effectively dissipating it. Various types of heat sinks, such as active and passive, each cater to specific cooling needs. These cooling champions are particularly effective when dealing with components that generate substantial heat, ensuring that their temperatures remain within acceptable limits.

Thermal Vias

Thermal vias are the communication channels that allow heat to traverse between different layers of the PCB. Think of them as thermal bridges connecting the layers. Via stitching, a technique that involves placing multiple thermal vias close together, enhances heat conduction. These unassuming channels ensure that heat finds its way out of the PCB, preventing localized overheating.

Copper Pour and Planes

With its exceptional thermal conductivity, copper can be harnessed as a heat-dissipating asset on the PCB. Copper pour and planes are like the conductive highways through which heat travels. They efficiently channel heat away from critical components, ensuring no region becomes a heat-trapping bottleneck. Dedicating a ground plane to heat dissipation can create a powerful thermal pathway.

Active Cooling Solutions

When the heated battle becomes fierce, active cooling methods come to the rescue. Fans, blowers, and even peltier devices are the heroes that actively circulate air and promote heat exchange. These solutions are particularly effective in scenarios where passive methods alone may fall short. High-power applications can benefit significantly from the strategic implementation of active cooling.

Proper Component Placement

In the intricate dance of PCB design, the placement of components holds significance beyond aesthetics. Component arrangement can greatly influence heat distribution. Heat-generating components should be kept apart while placing them near the board’s edge can help heat dissipate more effectively. A well-thought-out arrangement can minimize heat buildup and ensure that the electronic symphony plays on without a temperature-induced discord.

Thermal Pads and Compounds

Thermal interface materials, such as thermal pads and compounds, are the silent connectors that bridge the gap between components and heat sinks. Imagine them as the conduits of temperature equality. These materials enhance the thermal connection, facilitating the smooth flow of heat from components to heat-dissipating surfaces. They are particularly effective in situations where direct contact is challenging to achieve.

PCB Layout Optimization for Heat Dissipation

A well-optimized PCB layout is like a blueprint for efficient heat dissipation. Techniques like adjusting trace widths and minimizing vias can help heat flow more smoothly. Minimizing trace bottlenecks ensures that heat doesn’t encounter unnecessary resistance. By focusing on layout optimization, you pave the way for heat to escape without hindrance.

Enclosure Design for Airflow

The enclosure housing your electronic system is the habitat where heat management strategies come together. Strategic enclosure design facilitates proper airflow, the lifeline of heat dissipation. Vents, fans, and ducts play roles of crucial significance. Proper placement of these elements ensures that cool air enters, hot air exits, and the PCB environment remains conducive to efficient cooling.

Underfilling and Potting

Imagine providing not just armor but a fortress for your components. Underfilling and potting are techniques that enhance both mechanical support and thermal conductivity. These techniques provide added protection in harsh environments where temperature fluctuations and physical stresses are common. Encapsulating components in materials with excellent thermal properties creates a shield against external and internal threats.

Phase Change Materials

Enter the chameleons of thermal management: phase change materials. These materials undergo phase transitions as they absorb and release heat. They act as thermal buffers, absorbing excess heat during periods of high power consumption and releasing it when the system demands cooling. By harnessing the magic of phase changes, you maintain consistent temperatures, preventing sudden spikes that could otherwise jeopardize your components.

Thermal Simulation Software

In the digital age, the art of thermal management has evolved through simulation. Thermal simulation software is the crystal ball that lets you predict how heat will flow within your design. By inputting various parameters, you can visualize potential hotspots, identify areas of concern, and optimize your design before the first prototype is even built. This predictive power enables you to fine-tune your thermal management strategy with precision.

Testing and Iteration

As the saying goes, the proof is in the pudding. Testing is the ultimate validation of your thermal management strategy. Building prototypes and subjecting them to real-world conditions helps you understand how your design performs in practice. Test results are invaluable feedback that informs iterative improvements. The synergy between testing and iteration ensures that your thermal management approach evolves, reaching a state of optimal efficiency.

Benefits of Effective PCB Thermal Management

Effective PCB thermal management isn’t just a mere technical concern; it’s a strategic investment that yields a multitude of significant benefits. As electronic devices become more complex and compact, the heat generated within them becomes a critical factor that can significantly impact performance, reliability, and overall lifespan. Let’s delve into the in-depth benefits that arise from implementing a comprehensive and efficient PCB thermal management strategy:

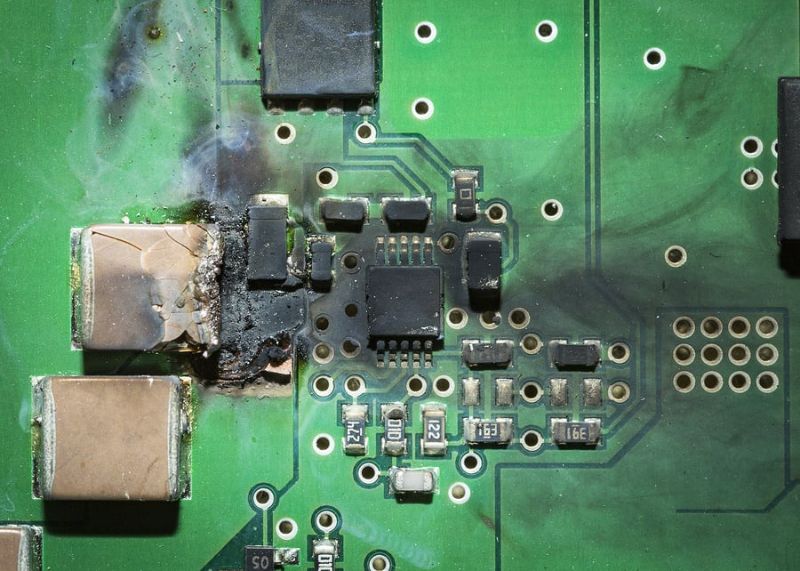

Enhanced Device Reliability and Longevity

One of the primary advantages of effective PCB thermal management is the substantial improvement in device reliability and longevity. Electronic components, especially modern integrated circuits, are designed to operate within specific temperature ranges. Excessive heat can accelerate the degradation of these components, leading to premature failure. By maintaining components at optimal temperatures, you mitigate the risks of thermal-induced stress, ensuring that they operate within safe limits. This translates into extended component lifespan and reduced instances of unexpected failures, thereby enhancing the overall reliability of your electronic systems. Proper electronics pcb materials selection, such as those with high thermal conductivity, further contribute to effective heat dissipation.

Improved Electrical Performance

Temperature and electrical performance are closely intertwined. The electrical properties of components can change with temperature fluctuations, potentially causing deviations in their behavior. Effective thermal management helps maintain a consistent operating temperature, ensuring that components perform consistently within their specified electrical characteristics. This is particularly critical in applications that demand precise and stable signal processing, where even minor variations can lead to signal integrity issues and compromised data accuracy.

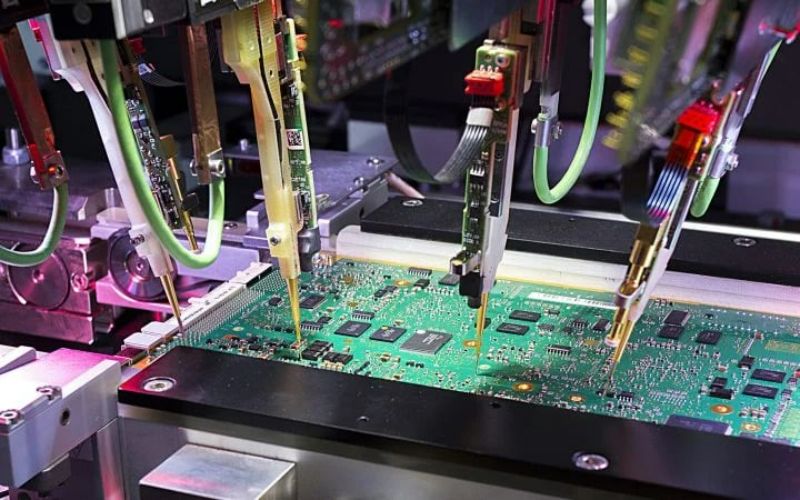

Enhanced Overall System Performance

Electronic devices are designed with performance in mind, whether it’s a high-speed server, a sophisticated medical instrument, or a consumer gadget. Heat can be a significant performance bottleneck. When components overheat, they may throttle their performance or trigger protective mechanisms to prevent damage. Effective thermal management ensures that components can operate at their intended frequencies and power levels without throttling, resulting in sustained and reliable performance. Proper pcb fabrication techniques that consider heat dissipation mechanisms during the manufacturing process play a crucial role in achieving this outcome.

Prevention of Critical System Failures

In many applications, especially safety-critical systems such as automotive electronics and aerospace controls, even a momentary failure can have catastrophic consequences. Overheating-induced component failures can lead to system crashes, malfunctions, and potentially life-threatening situations. By proactively managing heat, you reduce the likelihood of such failures and contribute to the overall safety and integrity of the systems in which your PCBs are integrated.

Cost Savings

Implementing a robust thermal management strategy can result in significant cost savings over the lifecycle of a product. Consider the expenses associated with repairing or replacing components that fail due to overheating. These costs extend beyond the mere replacement of parts; they include labor, downtime, and potential damage to the reputation of your brand. By preventing overheating-related failures, you not only save on component replacement costs but also avoid the ripple effects that such failures can trigger. Optimal pcb materials selection and electronics pcb fabrication practices can minimize heat-related failures and associated costs.

Energy Efficiency

Heat is detrimental to components and an indicator of energy inefficiency. Inefficient thermal management often requires extra cooling mechanisms, such as larger fans or additional heat sinks, which consume more power. By effectively managing heat, you can optimize cooling mechanisms, potentially reducing the power consumption of these cooling solutions. This energy efficiency lowers operational costs and aligns with sustainability goals in an era where energy conservation is paramount.

Minimized Design Iterations and Prototyping Costs

A poorly managed thermal design can lead to surprises during prototyping and testing phases. Unexpected overheating issues may necessitate design revisions, which incur additional costs and extend development timelines. By employing effective thermal management techniques from the outset, you minimize the chances of encountering significant thermal challenges during testing. This streamlines the prototyping process, reduces design iterations, and accelerates time-to-market. Proper pcb fabrication practices ensure that the designed thermal management techniques can be effectively implemented in the physical PCB.

Enhanced Customer Satisfaction

Devices that exhibit consistent performance, high reliability, and resistance to overheating-related issues lead to satisfied customers. Whether it’s a consumer device or an industrial solution, end-users value products that function reliably and seamlessly under various conditions. Effective thermal management contributes to the overall positive user experience, building trust in your products and brand.

Conclusion

In the fast-paced world of electronics, where innovation races forward, effective PCB thermal management stands as a steadfast guardian. We’ve journeyed through twelve dynamic techniques that empower you to wield mastery over heat. From heat sinks to simulation software, each technique plays a unique role in the grand symphony of thermal management. As you embark on your electronic design endeavors, remember that proactive thermal management isn’t just a choice—it’s a necessity. By integrating these techniques into your design process, you pave the way for electronic systems that operate with efficiency, reliability, and resilience against overheating challenges.