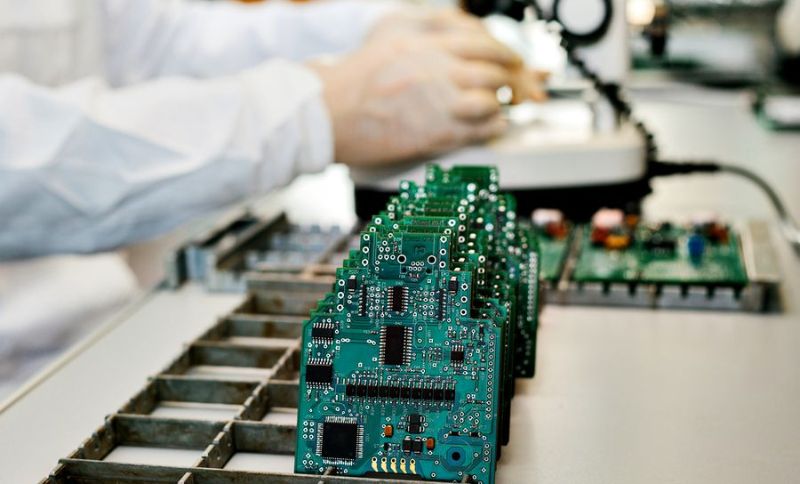

The world relies on intricate and powerful tools – from smartphones and laptops to medical equipment and airplanes. At the heart of these marvels lies the printed circuit board (PCB), a complex tapestry of electronic components that facilitates communication and function.

This is where the concept of sustainable development comes in – meeting our present needs for PCBs without even compromising to meet the ability of future generations. Sustainable PCB manufacturing strives to minimize environmental impact while ensuring responsible production practices.

The Environmental Footprint of PCB Manufacturing

-

Material Acquisition

Raw materials like copper, resins, and laminates used in PCBs come from mining and refining processes that can generate waste and air pollution. According to a UNEP or United Nations Environment Programme research from 2021, the electronics sector is accountable for 7% of the world’s industrial waste production.

-

Chemical Usage

PCBs must be cleaned, etched, and finished using a variety of chemicals, including plating solutions, acids, and solvents. These chemicals can damage wildlife and contaminate water sources if disposed of improperly.

-

Energy Consumption

The energy used to power PCB fabrication equipment, lighting, and climate control systems is significant. This dependence on fossil fuels hastens climate change by increasing greenhouse gas emissions.

-

Waste Generation

The manufacturing process generates waste streams, including spent chemicals, etching solutions, and scrap materials. Improper waste management can cause environmental pollution & resource depletion.

-

Circuit Board Assembly and Soldering

While a separate step from PCB manufacturing, circuit board assembly (CBA), which involves soldering electronic components onto the PCB, also uses materials that can have environmental consequences. While eliminating lead hazards, lead-free solders can still contain other potentially harmful elements like silver. Additionally, flux, used to clean surfaces before soldering, can be corrosive if not disposed of properly.

The Responsibility of PCB Manufacturers

Compliance with Regulations

Although environmental laws differ from place to place, most contain tight limits regarding handling chemicals, trash disposal, and emissions. Manufacturers must maintain current knowledge of these regulations and ensure that their procedures comply.

Sustainable Practices

Manufacturers can take a proactive stance towards environmental conservation, surpassing mere compliance. Here are some critical areas for improvement:

-

Reducing Chemical Usage

Hazardous waste creation can be considerably decreased using water-based cleaners, closed-loop chemical recycling systems, and low- or no-chrome plating techniques.

-

Energy Efficiency

Low- or no-chrome plating methods, closed-loop chemical recycling systems, and water-based cleansers can significantly reduce hazardous waste production.

-

Waste Management

It is crucial to put in place a strong waste management system that properly separates, treats, and recycles different waste streams.

-

Material Selection

Environmental risks can be considerably decreased by using lead-free and eco-friendly materials for PCB fabrication and CBA components like solders and fluxes.

-

Responsible Supplier Selection

Partnering with suppliers and prioritizing sustainability in their operations ensures a greener supply chain.

Sustainable Practices in Action

Several PCB manufacturers around the world are demonstrating leadership in sustainable practices:

-

Energy Efficiency

Companies are adopting LED lighting, optimizing ventilation systems, and implementing process automation to reduce energy consumption.

-

Water Conservation

Closed-loop water recycling systems are being used to reduce the amount of water used in the etching and cleaning processes.

-

Material Innovation

The main areas of research and development are using biodegradable materials and lead-free solders with low environmental effects and investigating substitutes for conventional etching chemicals.

Benefits of Sustainable PCB Manufacturing

Printed circuit boards (PCBs) are the essential building blocks of modern electronics, from smartphones to complex medical devices. However, the traditional manufacturing process can have a significant environmental impact.

Thankfully, sustainable PCB manufacturing practices are gaining traction, offering a win-win situation for both the environment and businesses.

-

Reduced Costs

Traditional PCB manufacturing processes can generate significant waste through materials like scrap metal from etching and leftover chemicals used in circuit board soldering. Sustainable practices focus on minimizing this waste.

Furthermore, recycling initiatives can extract useful components from PCBs that are thrown away, which lowers the demand for virgin resources. Implementing water conservation measures and optimizing energy use through energy-efficient equipment result in cost savings.

-

Enhanced Brand Image

Today’s consumers are increasingly environmentally conscious and make purchasing decisions based on the company’s commitment to sustainability. A business can cultivate a positive brand image by demonstrating a dedication to eco-friendly practices in PCB manufacturing.

This can attract environmentally responsible customers willing to pay a premium for products made with sustainability in mind.

-

Regulatory Compliance

Environmental rules are a dynamic field that is constantly changing. Compliance with these requirements is essential for any manufacturer of printed circuit boards. Businesses may remain ahead of the curve & avoid possible fines or legal problems by implementing sustainable practices.

Manufacturers can ensure their goods fulfill environmental safety standards by utilizing materials that comply with the Restriction of Hazardous Substances (RoHS) guidelines and implementing lead-free soldering procedures. This lowers the possibility of legal ramifications and shows a dedication to ethical manufacturing methods.

-

Improved Resource Management

A culture of effective resource management is fostered via sustainable PCB production. Businesses can guarantee the long-term availability of resources required for production by reducing waste and optimizing the use of recycled materials. This encourages long-term corporate sustainability in addition to helping the environment by lessening the demand for natural resources.

Furthermore, innovation in fields such as material science can be stimulated by sustainable practices, creating more environmentally friendly substitutes for conventional PCB components.

The Road Ahead for Sustainable PCB Manufacturing

The goal of sustainable PCB manufacturing is an ongoing task. To accelerate advancement, industry collaboration is essential. Here are a few crucial areas to watch in the future:

-

Standardization of Sustainable Practices

A more fair playing field can be achieved by exchanging best practices and creating industry-wide standards for sustainable PCB manufacture.

-

Government Incentives

Wider implementation might be encouraged by government efforts that provide tax advantages or subsidies to businesses that adopt sustainable practices.

-

Consumer Awareness

Demand for sustainable PCBs can be increased by educating consumers about the effects electronics have on the environment and motivating them to purchase items from responsible manufacturers.

Conclusion

Without sacrificing technological advancement, PCBLOOP guarantees a healthier planet by adopting sustainable methods and embracing environmental responsibility. The electronics manufacturing sector may lead toward a more environmentally friendly future by employing persistent innovation and cooperative efforts.