Company Profile

Company Profile

With a legacy spanning over 15 years, was foundered by Yang Xiaolin,Wang Wenjun and Zhou Xianfeng initially to provide design solution to domestic clients, PCBLOOP emerges as a star of excellence in the electronic design and manufacturing industry. Founded in Shenzhen, the heart of technological innovation, PCBLOOP’s journey began with a vision to be the premier partner of choice for businesses seeking excellence in electronic design and manufacturing, driving technological advancement and fostering global collaborations.

In a world where excellence is the norm and innovation is the key to success, PCBLOOP stands tall as a beacon of reliability, ingenuity, and customer-centricity. Our legacy of expertise, commitment to quality, relentless pursuit of innovation, and unwavering dedication to customer satisfaction define us not just as an outsourcing company, but as a trusted partner in shaping the future of electronic design and manufacturing. Join us on this journey of excellence and innovation, where every connection with PCBLOOP is a promise of quality, innovation, and lasting satisfaction.

Vision

To be the premier partner of choice for businesses seeking excellence in electronic design and manufacturing, driving technological advancement and fostering global collaborations.

Mission

To empower innovation through cutting-edge electronic design and manufacturing solutions, enabling businesses to thrive in a rapidly evolving technological landscape.

Values

Quality Excellence

Commitment to delivering high-quality, reliable electronic solutions that exceed industry standards.

Innovation

Embrace creativity and technological advancements to stay at the forefront of electronic design trends.

Customer-Centric Approach

Prioritize customer satisfaction by understanding their needs and delivering tailored solutions.

Integrity

Uphold the highest ethical standards in all business practices, ensuring transparency and trust.

Collaboration

Foster a culture of collaboration internally and externally to foster synergistic partnerships and mutual growth.

Sales Proposition

Implement lean manufacturing principles and process optimization techniques to reduce waste, improve efficiency, and lower production costs.

Utilize advanced automation and robotics to streamline manufacturing processes and increase productivity.

Offer value engineering services to identify cost-saving opportunities without compromising product quality.

Establish strategic partnerships with component suppliers to negotiate favorable pricing and ensure timely availability of materials.

Adopt agile product development methodologies to accelerate the design and prototyping phases.

Offer rapid prototyping services to quickly iterate and validate designs before full-scale production.

Maintain close collaboration and communication with clients throughout the design and manufacturing process to minimize delays and ensure efficient project management.

Leverage advanced manufacturing technologies, such as 3D printing and surface mount technology (SMT), for faster and more precise production.

Develop a deep understanding of relevant regulations and standards to ensure compliance throughout the design and manufacturing process.

Establish robust quality management systems to monitor and document compliance with regulatory requirements.

Employ certification experts who can guide clients through the certification process and facilitate compliance audits.

Maintain thorough documentation and traceability to demonstrate compliance and provide transparency to clients.

Implement strict access controls, confidentiality agreements, and non-disclosure agreements (NDAs) to safeguard client’s intellectual property.

Establish secure systems and protocols to protect sensitive data throughout the design and manufacturing process.

Clearly define and enforce IP protection policies throughout the organization and train employees on the importance of confidentiality.

Regularly update security measures to stay ahead of potential threats and vulnerabilities.

Build strong relationships with trusted suppliers and distributors to ensure a reliable supply chain.

Conduct thorough supplier audits to assess their capabilities, quality standards, and adherence to ethical practices.

Implement supply chain visibility tools and processes to track and manage inventory, ensuring timely availability of components.

Develop contingency plans and alternative sourcing strategies to mitigate risks associated with supply chain disruptions.

Invest in continuous learning and development programs for employees to stay updated with the latest technologies and design methodologies.

Collaborate with technology partners and research institutions to access cutting-edge knowledge and expertise.

Foster an innovative culture within the organization to encourage the exploration and adoption of emerging technologies.

Provide technology consulting services to clients, guiding them on the integration of new technologies into their products.

Establish training and mentorship programs to develop and retain skilled professionals within the organization.

Collaborate with universities and educational institutions to bridge the skill gap by providing internships, co-op programs, and career development opportunities.

Engage in industry associations and participate in knowledge-sharing events to attract and network with talent.

Offer design and manufacturing consulting services to clients, providing them access to specialized expertise and addressing skill gaps in their own teams.

Maintain a customer-centric approach, actively listening to clients’ unique requirements and providing tailored solutions.

Offer flexible manufacturing capabilities to accommodate customizations, small-batch productions, and quick turnaround times.

Develop modular design approaches and flexible manufacturing processes to enable easy customization and scalability.

Foster strong communication channels with clients, encouraging open dialogue and collaboration to understand their evolving needs and preferences.

By implementing these approaches, a design and manufacturing service company can effectively address the pain points of clients in the electronics industry, strengthen their relationships, and provide value-added solutions that meet their specific needs and preferences.

Production Process Control and Quality Insurance

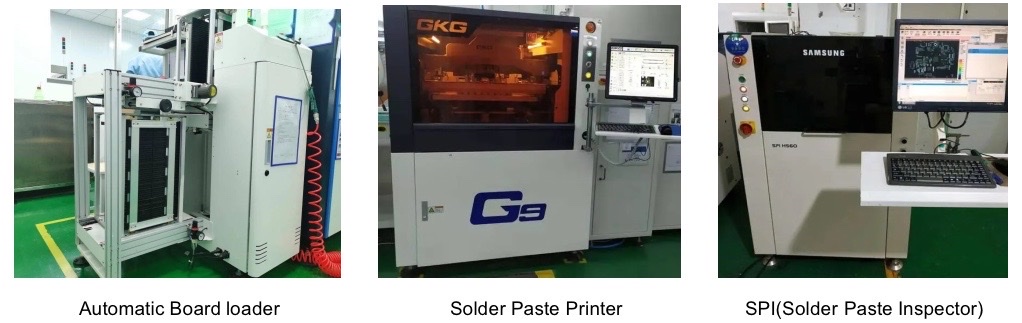

SPI (Solder Paste Inspection)

AOI(Auto Optical Inspection)

First-article Inspection Equipment

In-line Visual Inspection Before Reflow

Pre-Shipment Full Inspection for DIP

Equipments & Workshops