Imagine a world where printed circuit boards (PCBs) are manufactured with unparalleled speed, precision, and consistency—all without human error. Technological advancement has become synonymous with efficiency and precision. One industry that has significantly benefited from this trend is PCB manufacturing.

With increasing demand for sophisticated and highly functional electronics, automation technology has revolutionized the production of printed circuit boards (PCBs).

But what exactly is the role of automation technology in manufacturing PCBs, and how does it impact the industry’s efficiency? Could it answer challenges faced by low-volume Printed Circuit Board manufacturing services and large-scale manufacturers?

Let us discuss it all in detail in this blog.

The Rise of Automation in PCB Manufacturing

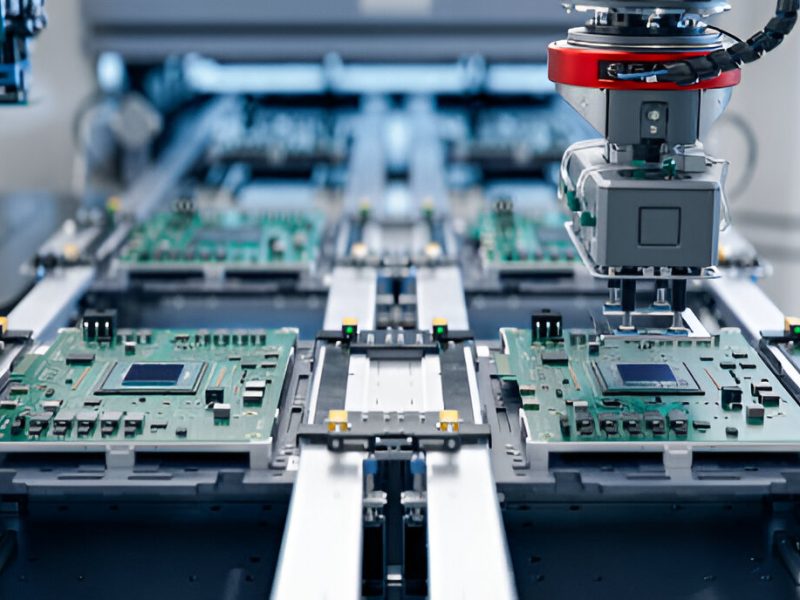

Printed Circuit Board manufacturing has revolutionized because of automation, which has increased productivity, streamlined procedures, and improved product quality. Automation technology gives producers more throughput, accuracy, and consistency. It can take many forms, from robotic equipment to sophisticated software.

Automation has several benefits, notably reducing human error—a crucial element in guaranteeing PCB reliability.

Key Applications of Automation Technology in PCB Manufacturing

Automation technology, as applied to the manufacturing of PCB, is the minimal human intervention in the design, fabrication, assembly, & testing of printed circuit boards through the use of robotics, artificial intelligence (AI), and advanced software.

Automation has several benefits since it can do repetitive operations quickly and precisely.

- Automated Assembly

Attaching the components is necessary after the board is built. Conventionally, this was done manually, embracing human errors. These days, devices like pick-and-place robots and Surface-Mount Technology (SMT) can assemble even the smallest components with unmatched accuracy.

Automation has brought innovative ways to speed up your PCB assembly process, reducing production time and ensuring components are precisely placed.

- Design Automation

automation technology in PCB design enable engineers and designers to produce more complex and helpful PCBs in less time. Sophisticated software also makes faster validation and prototyping possible, helping manufacturers avoid expensive errors.

Automation also plays a crucial role in designing PCBs that meet the unique needs of low-volume production. For instance, companies offering low-volume services for PCB manufacturing can quickly iterate and adjust their designs without having to start from scratch, saving time and resources.

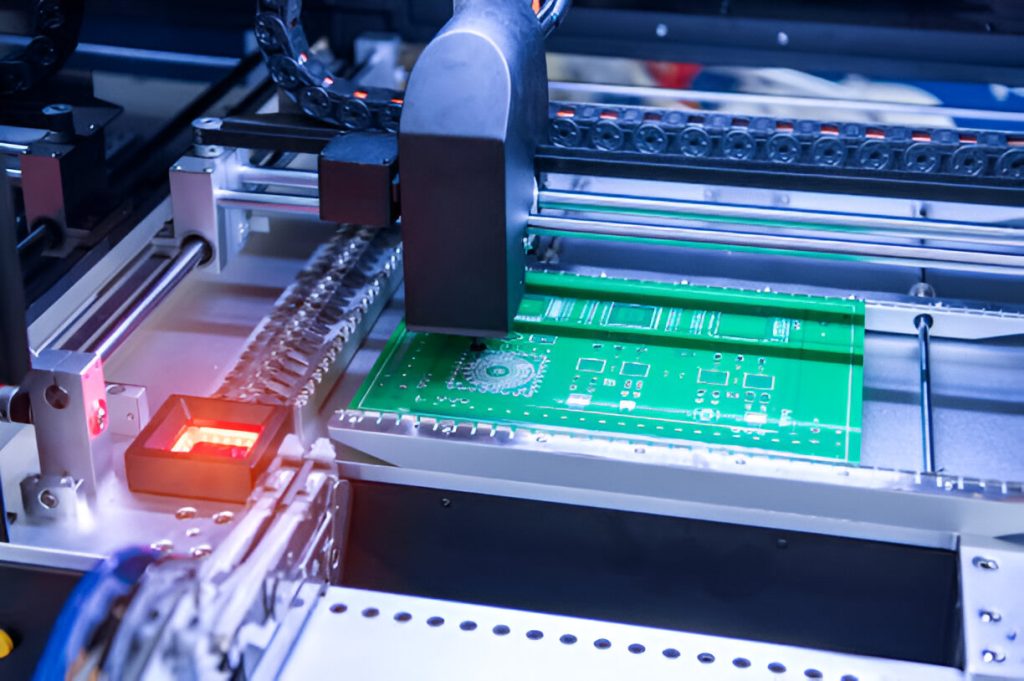

- Automated Fabrication

Copper layers are etched, laminated, and precisely electrically connected during PCB manufacture. Automated equipment, such as Computer Numerical Control (CNC) drilling machines, ensures board fabrication accuracy, which is especially important for multi-layer PCBs.

Integrating automated fabrication equipment can decrease material waste by up to 20% and enhance production speed by 30%–40%. Automation guarantees more accurate customization and quicker turnaround times for low-volume circuit board manufacturing services.

- Testing and Quality Control

Quality is of utmost importance in the Printed Circuit Board manufacturing industry, particularly in sectors like healthcare, aerospace, and automotive, where defective components can have catastrophic effects. Every PCB is meticulously inspected for flaws by automated testing technologies, including Automated Optical Inspection (AOI) and Automated X-ray Inspection (AXI).

Additionally, automation helps in the early detection of possible design defects, sparing producers from expensive rework.

The Benefits of Automation in PCB Manufacturing

Automation technology brings several advantages to the manufacturing of PCBs, directly impacting efficiency, cost-effectiveness, and product quality.

Here are some key benefits driving the shift toward automation:

- Increased Efficiency and Productivity

Automation speeds up the entire manufacturing process by reducing the need for human intervention. For businesses that specialize in low-volume printed circuit board manufacturing services, this enhanced efficiency might result in higher client satisfaction and quicker delivery times.

- Cost Reduction

Automation significantly cuts costs by reducing human error, material waste, and production time. Companies can maintain lower operating expenses, and the savings can be passed on to customers. Automation allows small-batch manufacturers to remain competitive without sacrificing quality.

- Scalability

Thanks to automated technologies, PCB manufacturers can simply increase production in response to demand. Whether generating a few prototype boards or ramping up for mass production, automation gives flexibility.

- Enhanced Customization

In low-volume PCB fabrication, automation enables more personalization. Manufacturers don’t need to take much time off to quickly adjust designs and production procedures. This is particularly important for startups and businesses requiring unique PCB designs.

- Improved Precision and Quality

Every PCB is built to exact specifications thanks to automation. This is critical for sectors like telecommunications and medical devices that demand extreme precision. Automated procedures guarantee constant quality and lower the possibility of flaws that can cause a product to fail.

Coupled with advanced quality assurance and testing methods to create excellent electronic products, automation ensures that each PCB meets the highest industry standards, reducing defects and improving reliability.

Challenges in Adopting Automation Technology

While automation offers numerous benefits, it is not without its challenges. Some of the obstacles manufacturers face when implementing automation technology include:

- High Initial Costs: Investing in automated equipment and software can be expensive, particularly for small enterprises. However, the long-term benefits in operational costs generally justify the expenditure.

- Training and Skill Development: Automation has made it necessary for trained professionals to run and maintain these cutting-edge devices. Training employees is an essential investment for a seamless shift to automated procedures.

- Complexity in Low-Volume Production: Even though automation has many advantages, it can also provide difficulties for low-volume Printed Circuit Board manufacturing services since smaller orders may not always warrant the setup time for specialized machinery. Nonetheless, flexibility to accommodate short production runs is becoming increasingly available in modern automation techniques.

Future of Automation in PCB Manufacturing

The development of automation technology will significantly impact PCB production in the future.

The printed circuit board (PCB) industry is anticipated to increase by USD 19.05 billion from 2022 to 2027, growing at a CAGR of 5.05% over the projected period. As automation technology continues to evolve, the PCB manufacturing industry will likely see even more efficient and cost-effective solutions.

The PCB sector is positioned for even higher levels of innovation with the advent of sector 4.0 and the integration of AI, ML, and big data analytics. One day, intelligent automation systems could accomplish autonomous PCB design, fabrication, and testing, cutting prices and manufacturing times.

Conclusion

The adoption of automated technology in PCB production has changed the industry. Automation has increased productivity, cut costs, and improved quality everywhere, from design and fabrication to assembly and testing. For businesses offering low-volume Printed Circuit Board manufacturing services, automation provides the flexibility and precision needed to meet their unique requirements.

The application of automation technology in the manufacturing of PCBs has revolutionized the industry. From design and fabrication to assembly and testing, automation has improved efficiency, reduced costs, and enhanced quality.

Looking ahead, automation will surely become even more of a driving force behind innovation in PCB manufacturing. By embracing automation, PCB manufacturers are improving their bottom line and shaping the future of technology.

Companies like PCBLOOP, specializing in printed circuit board manufacturing, are at the forefront of this transformation. They offer high-quality, efficient, and customizable solutions to satisfy the manufacturing world’s growing demands.