Automation has improved product reliability and sped up PCB assembly processes by revolutionizing the printed circuit board (PCB) sector. By fully automating the PCB manufacturing process, numerous ways exist to raise the production yield.

These complex boards are the basis of many electrical gadgets, carefully filled with different circuit board components. The need for PCBA production that is quicker, more effective, and more dependable is growing as technology develops. This is where automation – especially the use of robots – becomes revolutionary.

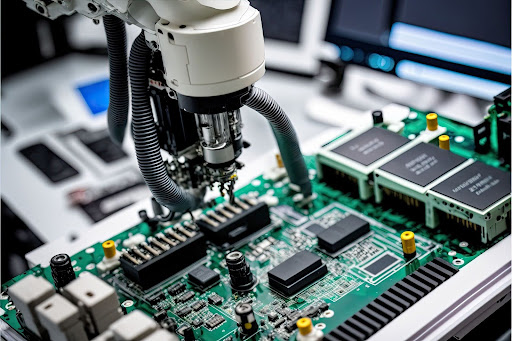

The Rise of Robotics in PCB Assembly

Robotics has significantly sped up PCB manufacturing while upholding quality standards. These cutting-edge materials have produced intricate designs that effectively accomplish their objectives.

Furthermore, many electronic organizations are starting to use automated systems with direct programming skills to test new ideas or concepts quickly so they may be implemented more affordably and on a broader scale.

-

Enhanced Speed and Throughput

When it comes to operations, robots perform much faster than human beings. Printed Circuit Board Assembly throughput will significantly rise due to their remarkable accuracy and consistency in handling repeated jobs like component placement.

-

Improved Precision

Even with minor components, robotic arms outfitted with high-resolution cameras and complex programming enable accurate component placement, reducing errors in installation and guaranteeing constant quality.

-

Reduced Labor Costs

Robotic systems may need a large initial investment, but the advantages outweigh the drawbacks in the long run. Robots can save money on labor costs by automating repetitive jobs that humans have historically completed.

Robots in Action: Key Applications in PCB Assembly

Robots are used in PCB Assembly for purposes other than speed and accuracy. Let’s examine some of the significant functions that robots perform in a modern production line:

-

Component Placement

The most well-known application is this one. Components ranging from small resistors and capacitors to intricate integrated circuits (ICs) are precisely picked and placed onto the correct places on the printed circuit board (PCB) by robots outfitted with grippers and vision systems.

-

Soldering

It is possible to program robotic arms to perform high-precision soldering jobs. Their remarkable accuracy in controlling the soldering iron tip ensures ideal solder bond formation and reduces the possibility of errors.

-

Inspection and Testing

Automated optical inspection (AOI) systems can connect robots to analyze soldered junctions and detect possible flaws visually. Furthermore, printed circuit board assemblies can be moved around different testing stations by robots designed to handle them during functional testing.

-

Material Handling

Circuit boards and other components can be moved by robots effectively throughout the PCB assembly line, guaranteeing a steady and uninterrupted flow of materials.

Advantages of Robotics Integration Beyond Efficiency

-

Reduce Human Errors

Accuracy is essential to the manufacturing industry, and even the most hardworking human worker can become exhausted. On the other hand, robots are the epitome of constancy.

They complete monotonous jobs with perfect accuracy, removing the chance of mistakes brought on by fatigue or distractions. This results in fewer defective goods and an output of greater overall quality.

-

Improve Working Conditions

Human workers may be exposed to health hazards when performing repetitive jobs or working with dangerous products. Robots, protecting human welfare, perform these difficult jobs.

This promotes a safer and more engaging work environment by freeing employees to concentrate on strategic activities that call for human ingenuity and innovation.

-

Increased Flexibility

Manufacturing is a dynamic field, constantly evolving with new designs and materials. Robots, unlike traditional production lines, offer remarkable flexibility. They can be reprogrammed to handle a broader range of components and layouts, seamlessly adapting to changing production needs.

This agility ensures manufacturers can respond quickly to market demands & stay ahead of the curve.

-

Consistency

Consider a product whose quality is the same in every single unit. This desire comes true thanks to robots. Their dependable and accurate movements guarantee that each part is assembled and completed precisely, producing a consistently high-quality finished product throughout the production run.

This consistency encourages consumer satisfaction and strengthens brand confidence.

-

Improved Production Speed

Robots are indeed fast. However, their speed advantage extends beyond only producing goods more quickly. Robots optimize the entire production process by reducing errors and streamlining processes.

This results in quicker turnaround times, offering you a competitive edge by enabling you to meet deadlines and get products to market sooner.

-

Efficient Material Handling

Robots are excellent at handling materials and assembling them. They can efficiently move parts and completed goods along the manufacturing line, guaranteeing a constant flow of resources that keeps everything functioning like a well-oiled machine.

Delays are reduced, and production efficiency is increased because of this optimized material management.

Challenges and Considerations of Robotics Integration

While robots offer many advantages, integrating them into your production line isn’t without its hurdles. Here are some roadblocks to consider:

-

Initial Investment Costs

Cutting-edge technology comes at a cost. Purchasing and deploying robotic equipment might cost a lot of money upfront. Nonetheless, the initial price barrier is frequently outweighed by the long-term gains in quality and efficiency.

-

Programming Complexity

Robots require complex programming to carry out their duties perfectly. This challenging task requires specialized knowledge and continuous maintenance to ensure the robots can adjust to shifting production requirements.

-

Space Requirement

It’s not exactly common knowledge that robots are little. Their motions and operational requirements require more floor space, which may require rearranging the layout or expanding the facility.

-

Possibility of Adding Multiple Errors

Robots are excellent at reducing errors, yet even one programming error can have far-reaching effects. A thorough inspection and testing procedure is essential to avoid a cascading series of mistakes after the robots are in operation.

-

Needs for Human Intervention

Even with their potential, robots aren’t quite ready to take over the entire show. Human interaction is still necessary for debugging, maintenance, and general production process oversight. The secret is striking the ideal mix between robotic efficiency and human competence.

The Future of Robotics in PCB Assembly

-

Smarter Vision

Even more sophisticated vision systems will enable robots to handle a greater range of components precisely.

-

AI on the Assembly Line

Artificial intelligence will play a larger role, allowing robots to adapt to changing designs and self-learn for continuous improvement.

-

Human-robot Collaboration

Collaborative robots designed to work safely alongside humans will usher in a hybrid approach that leverages both strengths.

Conclusion- A Symbiotic Future

Integrating robots into Printed Circuit Board assembly is revolutionizing the industry. These tireless machines offer many benefits, from enhanced speed and precision to improved working conditions. While challenges exist, the future holds exciting possibilities with advancements in AI and collaborative robots.

As a leading provider of high-quality PCB assembly services, PCBLOOP stays at the forefront of technological advancements. They offer a robust and efficient PCB assembly process, ensuring exceptional quality and fast turnaround times.

Contact PCBLOOP today and experience the future of PCB assembly.