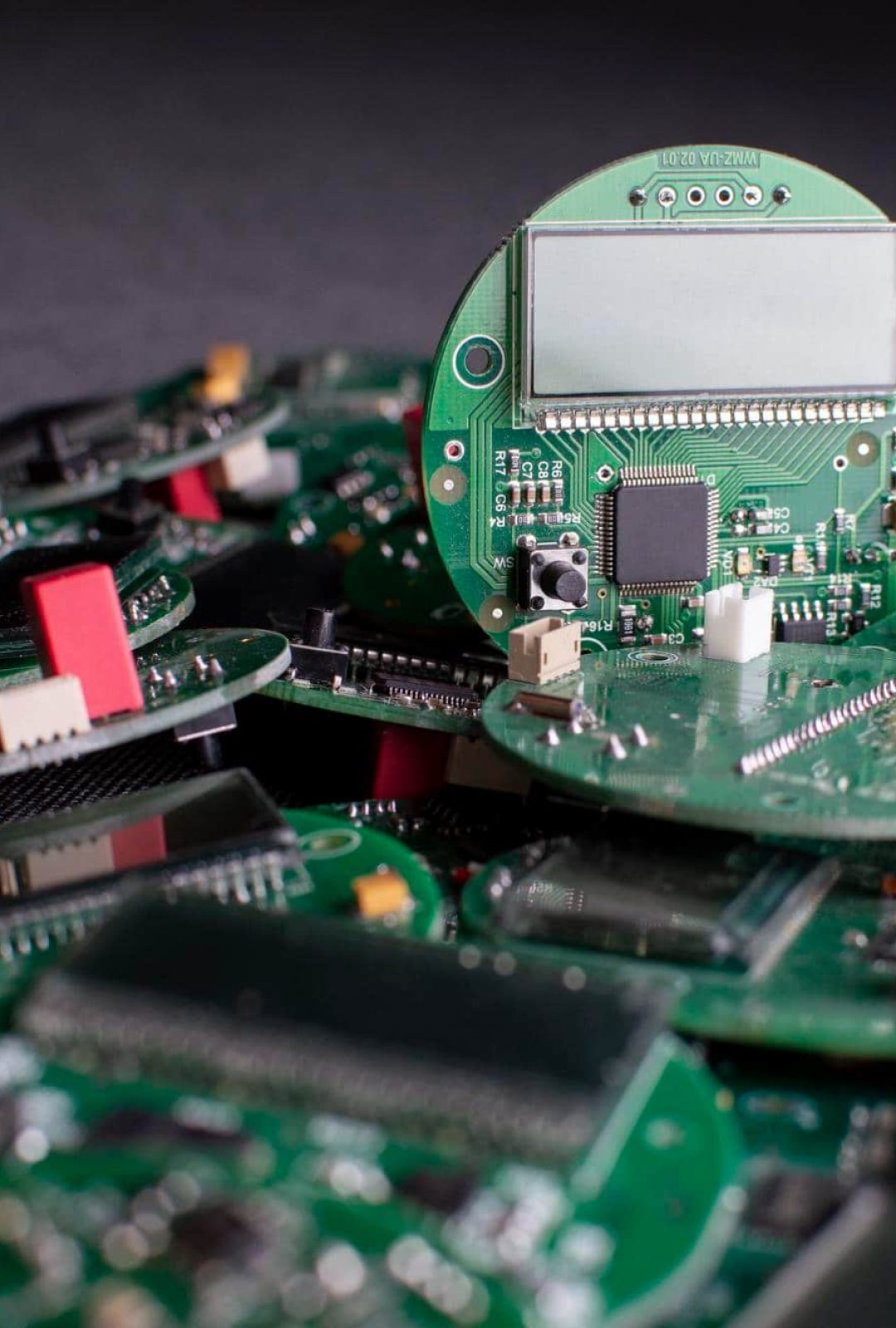

Accelerate Innovation: Expert Product Development and PCB Prototyping

From concept to creation, we transform your ideas into tangible products with speed and precision. Our end-to-end solutions cover design, engineering, printed circuit board prototyping service, and testing, ensuring a seamless prototype development process.

Why Work With Us

1. Cost and Efficiency:

- Implement lean manufacturing

- Utilize advanced automation and robotics

- Offer value engineering

- Establish strategic partnerships with component suppliers

2. Time-to-Market:

- Adopt agile product development methodologies

- Deliver high-quality PCB prototypes quickly using advanced techniques

- Maintain close collaboration and communication with clients

- Leverage advanced manufacturing technologies

3. Complex Regulatory Compliance:

- Develop a deep understanding of relevant regulations and standards

- Establish robust quality management systems

- Employ certification experts

- Maintain thorough documentation and traceability

4. Intellectual Property Protection:

- Implement strict access controls, confidentiality agreements, and non-disclosure agreements (NDAs)

- Establish secure systems and protocols

- Clearly define and enforce IP protection policies

- Regularly update security measures

5. Supply Chain Management:

- Build strong relationships with trusted suppliers and distributors

- Conduct thorough supplier audits

- Implement supply chain visibility tools and processes

- Develop contingency plans and alternative sourcing strategies

6. Technological Advancements:

- Invest in continuous learning and development programs for employees

- Collaborate with technology partners and research institutions

- Foster an innovative culture within the organization

- Provide technology consulting services to clients

7. Skill Gap:

- Establish training and mentorship programs

- Collaborate with universities and educational institutions

- Engage in industry associations and participate in knowledge-sharing events

- Offer design and manufacturing consulting services to clients

8. Customization and Flexibility:

- Maintain a customer-centric approach

- Offer flexible manufacturing capabilities

- Develop modular design approaches and flexible manufacturing processes

- Foster strong communication channels with clients

Comprehensive Product Development Services

We offer a full suite of product development and PCB prototype services tailored to your specific needs. Our expertise spans various industries, including consumer electronics, IOT devices, Wearable devices, industrial equipment, etc.

Our services process include:

- Concept Development & Design: We collaborate with you to refine your product vision, create detailed designs, and develop user-centered prototypes.

- Engineering & Analysis: Our experienced engineers utilize cutting-edge tools and techniques to ensure the functionality, performance, and manufacturability of your product. We perform rigorous testing and analysis, including FEA, thermal analysis, Reliability Test etc., to optimize your design for success.

- Prototyping: We offer a range of pcb prototype circuit board options, from rapid prototyping using 3D printing to fully functional prototypes using advanced manufacturing techniques. We’ll help you select the best approach based on your project requirements and budget.

- Testing & Validation: We conduct comprehensive testing to validate your product’s performance, reliability, and safety. Our testing capabilities e.g., environmental testing, functional testing, compliance testing.

- Pilot Production & Manufacturing Support: We can assist you with pilot production runs and provide support for transitioning your product to full-scale manufacturing.

Proven Success: Our Impact in Action

SmartSprinkler (IoT/Smart Home)

Challenge: Creating a reliable and cost-effective wireless communication module for a smart sprinkler controller. Existing solutions were either too expensive or unreliable in outdoor environments.

Solution: PCBloop designed a custom wireless module using a robust, low-power radio frequency (RF) transceiver. We optimized the antenna design for optimal range and performance in outdoor settings. We also developed firmware that ensured reliable communication even in challenging RF environments.

Results: The new wireless module provided a reliable connection range of over 300 feet, while consuming minimal power. The cost-effective design allowed SmartSprinkler to offer their product at a competitive price point, driving market adoption and increasing sales.

FitTrack (Wearable Technology)

Challenge: Developing a low-power heart rate monitor for a fitness tracker with extended battery life. Existing solutions consumed too much power, limiting the device’s usability.

Solution: PCBloop designed a custom low-power circuit using optimized components and power management techniques. We also developed firmware that minimized the heart rate sensor’s active time while maintaining accuracy.

Results: The new design reduced power consumption by 40%, extending the fitness tracker’s battery life by 25%. This key improvement allowed FitTrack to market their product with a longer usage time between charges, a significant advantage in the competitive wearables market.

Cutting-Edge Technology & Expertise

Our team of highly skilled engineers and designers leverages the latest technologies and tools to bring your product vision to life. We have extensive experience in e.g., schematics design, PCB Layout,firmware development,mechanical design, CAD/CAM software, 3D printing, CNC machining, injection molding. Our state-of-the-art facilities are equipped to handle projects of any size and complexity.

1) Embedded Development & Programming

PCBLOOP provides full-service embedded system development, including PCB design and embedded programming. Our company has experience in the following industries: industrial electronics, IOT devices, Wearable devices, and consumer products. We work with all embedded system components, including analogue and digital circuitry and intelligent controllers (microcontrollers, microprocessors, DSPs, FPGAs, etc.)

Embedded Services and Expertise:

- 3D Model of a Prototype Circuit Board Design

- Board design/circuit design

- Component selection

- Firmware development

- Platform selection

- Prototypes

- C, C++, Java, Assembly

- DSP & microprocessor development

- Field Programmable Gate Array (FPGA) development

- Device drivers & external communications protocols

- Documentation and testing

- Single board computers

2) Test & Measurement Automation

Our experienced team of programmers and engineers assists our clients in automating test systems using cutting-edge technologies. We have years of experience providing world-class solutions to leaders in R&D, manufacturing, quality, and certification testing.

Our adaptable and collaborative approach results in efficient, accurate, and robust test systems, as well as the tools to effectively analyze test data. We create systems using a wide range of software and hardware platforms (both custom and off-the-shelf), data acquisition systems, and control methods. VeriStand, SystemLink, anded. FlexLogger are all includ We are equally at ease developing custom turnkey systems or collaborating with your team on an existing system under development.

3) Manufacturing Automation and Intelligence

PCBLOOP offers industrial manufacturing automation and system integration services. Our expert engineers offer a wide range of services, from software development to full turnkey automation solutions. Mechanical design, electrical design, controls and software engineering, machine build, integration, and commissioning are among the services we offer. Our emphasis on controls and software engineering (including PLC, HMI, SCADA, and cloud integration) ensures that we provide clients with efficient and modern automation solutions.

Efficient & Transparent: Get a Quick Quote

We offer competitive pricing and flexible lead times to meet your project deadlines. Contact us today for a free consultation and a personalized quote.

What Our Clients Say

Frequently Asked Questions

We work with a wide range of clients, from start-ups to large corporations, across various industries. We have experience in designing and manufacturing custom electronics for a variety of applications, including IOT devices, industrial equipment, consumer electronics, and more. We can provide the support and guidance they need to bring their ideas to life. We understand the unique challenges our clients faced.We can offer flexible payment options and tailored solutions.

We provide a wide range of product design and manufacturing services, including electronic product concept design, hardware circuit design, software development, PCB layout, exterior and interior structure design, prototype production, mass production, supplier management, procurement services, other specific services and sales of some electronic products, etc. Our goal is to provide a full range of customized solutions based on customer needs.

The cost of product development varies depending on a number of factors, such as the complexity of the design, the number of prototype board required, and the volume of production. We will provide you with a detailed quote once we have a better understanding of your specific requirements.

Our prototype development process typically involves the following steps:

Requirements gathering: We will work with you to gather your product requirements and develop a detailed product specification.

Concept design: We will develop a concept design for your product, including schematics and PCB layout.

Prototyping: We will build a prototype of your product to test its functionality and performance.

Production: Once you are satisfied with the prototype, we will move into production and manufacture your product.

Our typical project timelines range from a few weeks to several months, depending on the complexity of the design and the number of prototypes required. We will provide you with a detailed project timeline once we have a better understanding of your specific requirements.

Yes, we provide after-sales support and maintenance services. Once your product is delivered, we will continue to work with you to provide the necessary technical support, troubleshooting and maintenance services to ensure the normal operation of the product and the satisfaction of your customers.

It is easy to start a project with us. You can contact us through our website or send an email to our customer service team. Please provide the project requirements and detailed description, and our team will contact you as soon as possible to discuss the project details and develop a cooperation plan.

There are a number of risks involved in developing an electronic product, such as technical challenges, regulatory compliance issues, and production delays. We have experience in mitigating these risks and will work with you to develop a plan to address them.

We provide complete documentation for our custom pcb prototype board designs, including schematics, PCB layout files, and a bill of materials, production files etc.

Yes, we offer design for manufacturability (DFM) services. DFM services can help you identify and address any potential manufacturing issues early in the design process.

Yes, we provide rapid circuit board prototyping service interms of bare PCB and PCB assembly.

Prototyping is an important step in the development process, as it allows you to test the functionality and performance of your product before moving into production.

Yes, we have a number of certifications and accreditations, including RoHS, ISO 9001, ISO 14001, and ISO 13485. These certifications demonstrate our commitment to quality, environmental sustainability, and medical device safety.