Did you know that a study estimated the size of the PCB market to be USD 86.76 billion in 2023 and USD 91.79 billion in 2024? It is projected to grow at a CAGR or compound annual growth rate of 5.8% from 2024 to 2033, reaching around 152.46 billion U.S. dollars by 2033.

In the fast-evolving world of electronics, time is more than just money—it’s the key to staying competitive. The race to bring innovative products to market is relentless, and every second counts.

However, when it comes to printed circuit board assembly (PCBA), even minor delays can cause significant setbacks, stalling your entire production line. Imagine having a brilliant design, only to find your assembly process dragging its heels, putting your deadlines at risk. It is important to speed up your PCB assembly process.

But how can you do it without compromising quality? You will learn from the tips mentioned in this guide to streamline and speed up your PCB assembly, which helps you meet your deadlines and exceed expectations and ensures your product reaches the market faster and more efficiently.

Let us dive deeper into the proven tips for faster PCB assembly.

What Do You Mean By PCB Assembly Process?

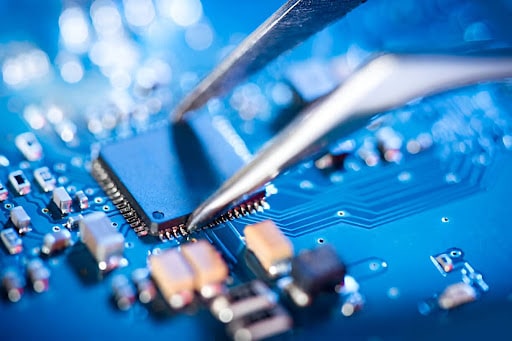

Printed circuit board (PCB) assembly is a vital step in the manufacturing process of electronic devices. It involves attaching various electronic components, such as resistors, capacitors, and integrated circuits, to a printed circuit board. The efficiency of the PCB assembly process directly impacts the overall production time and cost.

Therefore, optimizing this process to achieve faster turnaround times and reduce expenses is essential. The assembly process typically involves several key steps:

- Solder Paste Application: The PCB surface where the components are to be mounted is covered with solder paste.

- Component Placement: Circuit board components are placed onto the solder paste in precise locations.

- Soldering: The PCB is connected to the components, typically by wave or reflow soldering.

- Inspection and Testing: The best methods for PCB design testing and inspection are used here. The assembled PCB is inspected for defects and tested to ensure it functions as intended.

Each of these steps must be performed with precision and efficiency to ensure a successful PCB assembly.

Tips to Speed Up PCB Assembly Process

Here are ten proven tips that will help you accelerate your PCB assembly process:

1. Optimize Your PCB Design for Assembly

The design phase is the foundation of a fast and efficient PCB assembly process. By optimizing your PCB design for assembly, you can significantly cut down the chances of errors and delays.

Key Design Considerations:

- Component Placement: Ensure that circuit board components are placed logically with adequate spacing. Components should be aligned to minimize the chances of misalignment during assembly.

- Design for Manufacturability (DFM): Incorporate DFM principles into your design. This includes using standard component footprints, minimizing the number of unique components, and designing clear and accessible trace routing.

2. Use High-Quality Circuit Board Components

The quality of the components you use in your PCB assembly has a direct impact on both the speed and success of the assembly process.

Why Quality Matters:

- Fewer Defects: High-quality components are less prone to defects, which reduces the need for rework and inspection, thereby speeding up the assembly process.

- Consistent Performance: Reliable components ensure consistent performance across all units, reducing variability and potential delays in production.

Companies that prioritize sourcing high-quality components often experience fewer delays due to defective parts, which can otherwise slow down the entire assembly process.

3. Standardize Your Bill of Materials (BOM)

A well-structured and standardized Bill of Materials (BOM) can significantly streamline the procurement and assembly process.

Benefits of Standardization:

- Simplified Procurement: By standardizing components across different projects, procurement becomes more straightforward, reducing the time spent sourcing unique or specialized components.

- Reduced Assembly Errors: A clear and standardized BOM minimizes the likelihood of assembly errors caused by incorrect or missing components.

4. Implement Automated Optical Inspection

Automated Optical Inspection (AOI) is an essential tool for speeding up the PCB assembly process by quickly identifying defects in circuit board components.

Growing at a CAGR of 20.8%, the size of the global market for optical inspection systems is projected to reach USD 1660 million by 2026 from USD 646 million in 2021.

Advantages of AOI:

- Early Defect Detection: AOI systems can detect issues such as soldering defects, missing components, and misalignments early in the assembly process.

- Reduced Rework: Catching defects early reduces the need for time-consuming rework, ensuring a smoother and faster assembly process.

5. Choose the Right Assembly Partner

A well-managed supply chain is crucial to ensuring that all components arrive on time and in the right quantities, avoiding delays in the PCB assembly process.

Key Considerations

- Experience and Expertise: Select an assembly partner with extensive experience in handling similar projects and a deep understanding of printed circuit board assembly.

- Capacity and Flexibility: Ensure your partner has the capacity to handle your production volume and the flexibility to accommodate changes or unexpected challenges.

Companies that partner with experienced PCB assemblers, like PCBLOOP, often report faster turnaround times and higher quality outcomes.

6. Improve Component Handling

When assembling circuit boards, careful handling can greatly lower the chance of damage and assembly delays.

Best Practices:

- Proper Storage: Store components in a controlled environment to prevent damage from moisture or electrostatic discharge (ESD).

- Automated Handling: Where possible, use automated component handling systems to minimize manual errors and speed up the assembly process.

7. Optimize Supply Chain Management

A well-managed supply chain is crucial to ensuring that all components arrive on time and in the right quantities, avoiding delays in the PCB assembly process.

Supply Chain Strategies:

- Supplier Relationships: Establish trusting connections with reliable vendors to guarantee circuit board components are delivered on schedule.

- Inventory Management: Implement robust inventory management systems to track component availability and avoid shortages that could delay assembly.

8. Optimize Soldering Techniques

Soldering is a vital step in the PCB assembly process, and optimizing your soldering techniques can lead to significant time savings.

Best Practices:

- Reflow Soldering: Use reflow soldering for surface-mount components, as it is faster and more reliable than manual soldering.

- Temperature Control: Fine-tune the temperature profile of your reflow oven to match the specific components and materials you are using, reducing the risk of defects.

9. Implement a Just-In-Time (JIT) Inventory System

A Just-In-Time (JIT) inventory system can help you reduce lead times and speed up the PCB assembly process.

Benefits of JIT:

- Reduced Inventory Costs: JIT minimizes the amount of inventory you need to hold, reducing storage costs and the risk of component obsolescence.

- Faster Turnaround: With components arriving exactly when needed, you can start assembly immediately, reducing lead times.

10. Leverage Pick-and-Place Automation

Pick-and-place machines are invaluable in speeding up the placement of circuit board components, particularly for high-volume production runs.

Advantages of Automation:

- Increased Speed: Pick-and-place machines can place thousands of components per hour, far exceeding manual placement speeds.

- Improved Accuracy: Automated machines are highly accurate, reducing the risk of misplacement and subsequent rework.

Implementing these 10 proven tips can significantly speed up your PCB assembly process and improve overall production efficiency.

PCBLOOP: Your Trusted Partner in PCB Assembly

Partnering with an experienced and reliable service provider is crucial when it comes to speeding up your PCB assembly process. PCBLOOP is a leading name in the industry, offering comprehensive printed circuit board assembly services that are both fast and reliable.

From design to assembly, PCB manufacturing is an intricate process that PCBLOOP understands and excels at. Focusing on quality and efficiency, the company ensures that your projects are completed on time and to the highest standards.

Conclusion

By optimizing component placement, utilizing automated equipment, improving soldering techniques, and implementing effective inspection processes, you can reduce assembly time, enhance quality, and lower costs.

Additionally, considering emerging technologies, optimizing the assembling tips, and investing in employee training can further contribute to a more efficient and competitive PCB assembly process.

With a commitment to quality and speed, PCBLOOP ensures that your projects are completed on time and exceed industry standards. Whether you are optimizing your design or streamlining your assembly process, they remain your trusted partner for success in the fast-paced world of PCB electronics manufacturing.