In the realm of electronics, innovation knows no bounds. The pursuit of smaller, lighter, and more versatile devices has led to the evolution of flexible electronics technology. At the heart of this innovation lies Flexible Printed Circuit Boards (PCBs), revolutionizing how electronic devices are designed and manufactured. In this blog, we delve into the innovative practices shaping the landscape of Flexible PCB Manufacturing, exploring design considerations, assembly techniques, and emerging trends in production.

Understanding Flexible PCB Fabrication:

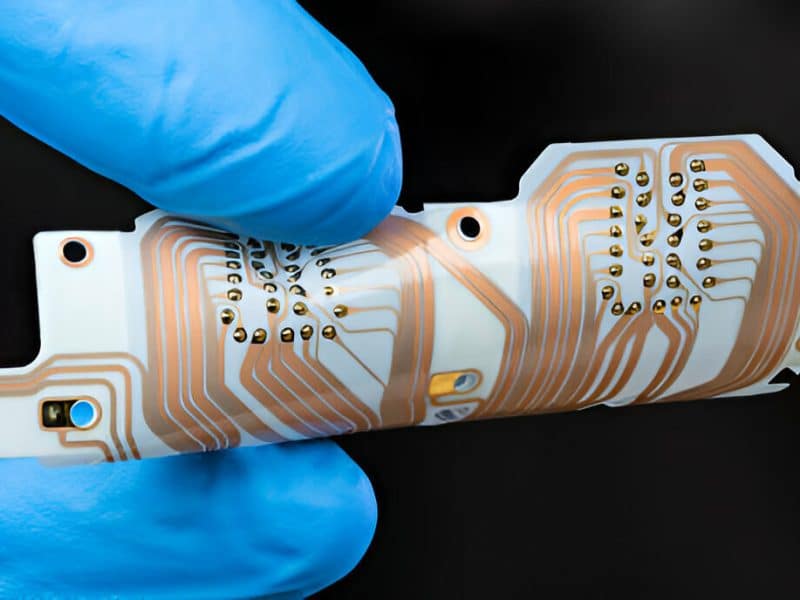

Flexible PCBs, also known as flex circuits, are made from flexible plastic substrates, such as polyimide or polyester. Unlike traditional rigid PCBs, flex circuits offer unparalleled flexibility, allowing them to conform to complex shapes and fit into tight spaces. The fabrication process of flexible PCBs involves several key steps, including substrate preparation, circuit patterning, component mounting, and final assembly.

Flexible PCB Design Considerations:

Designing a flexible PCB requires careful consideration of various factors to ensure optimal performance and reliability. Here are some key considerations:

- Bend Radius: Flex circuits are designed to bend and flex without compromising functionality. Determining the appropriate bend radius is crucial to prevent damage to the circuitry and ensure longevity.

- Component Selection: Choosing components that can withstand bending and flexing is essential for the durability of flexible PCBs. Flexible PCB assembly services often recommend using surface-mount components with flexible leads or compliant terminations.

- Thermal Management: Efficient heat dissipation is vital to prevent overheating and ensure the reliability of flexible PCBs. Designing thermal vias and incorporating heat sinks can help manage thermal issues effectively.

- Board Stiffness: Balancing flexibility with sufficient stiffness is essential to maintain structural integrity and prevent excessive bending or warping.

- High-Frequency Layout: Maintaining signal integrity in high-frequency applications requires careful routing and shielding techniques to minimize signal loss and electromagnetic interference.

- Attachment Method: The method used to attach components to flexible PCBs plays a significant role in determining the overall reliability and performance of the assembly. Standard attachment methods include solder joints, conductive epoxy, mechanical fasteners, and pressure-sensitive adhesives.

Assembly Techniques:

Flexible PCB assembly involves the attachment of components to the flexible substrate using various techniques. Some commonly used methods include:

- Solder Joints: Soldering is a widely used method for attaching components to flexible PCBs. Surface-mount components are soldered onto the flexible substrate using reflow or wave soldering processes.

- Conductive Epoxy: Conductive epoxy adhesives are used to bond components to flexible substrates, providing both mechanical and electrical connections.

- Mechanical Fasteners: Mechanical fasteners, such as screws or clips, are used to secure components to flexible PCBs, offering a robust attachment method suitable for high-stress environments.

- Pressure-Sensitive Adhesives: Pressure-sensitive adhesives (PSAs) provide a simple and cost-effective method for attaching components to flexible substrates. PSAs offer flexibility and ease of assembly but may require additional measures to ensure long-term reliability.

Emerging Practices in Flexible PCB Production:

As technology advances, so do the techniques and materials used in flexible PCB assembly services. Some emerging practices include:

- Additive Manufacturing: Additive manufacturing techniques like 3D printing are being explored to produce flexible PCBs with intricate designs and customizable features.

- Stretchable Electronics: Stretchable materials, such as elastomers and conductive polymers, enable the development of stretchable electronics capable of bending, twisting, and stretching without damage.

- Roll-to-Roll Processing: Roll-to-roll processing allows for the continuous fabrication of flexible PCBs on flexible substrates, offering scalability and cost-efficiency for high-volume production.

- Embedded Components: Embedding components directly into the flexible substrate eliminates the need for separate assembly steps, reducing size and weight while enhancing reliability.

Industries making use of flexible PCBs:

Printed Circuit Boards (PCBs) assembly have opened up new avenues for innovation across various industries. Their unique characteristics, such as flexibility, lightweight, and compactness, make them ideal for applications where traditional rigid PCBs fall short. Here are some industries that are making extensive use of flexible PCBs:

-

Wearable Devices:

The wearable technology industry has experienced exponential growth in recent years, driven by the demand for smartwatches, fitness trackers, and other wearable gadgets. Flexible PCBs play a crucial role in these devices, providing the necessary flexibility to conform to the contours of the human body while delivering reliable performance.

Whether it’s monitoring vital signs, tracking physical activity, or delivering notifications, flexible PCBs enable the seamless integration of electronics into wearable devices, enhancing user experience and functionality.

-

Medical Devices:

In the field of healthcare, flexible PCBs are revolutionizing the design and functionality of medical devices. From implantable devices, such as pacemakers and neurostimulators, to diagnostic equipment and wearable health monitors, flexible PCBs enable the development of compact, lightweight, and patient-friendly solutions. The flexibility of these PCBs allows medical devices to conform to the body’s natural contours, improving comfort and wearability.

Flexible PCBs also facilitate the integration of sensors, wireless communication, and advanced monitoring capabilities, enabling real-time health monitoring and personalized healthcare solutions.

-

Robotics:

Flexible PCBs play a vital role in the development of robotic systems, providing the necessary flexibility and durability to withstand the rigours of movement and manipulation. Whether it’s industrial robots used in manufacturing processes or robotic prosthetics designed to mimic human movements, flexible PCBs enable the seamless integration of electronics into robotic systems.

Flexible PCBs’ lightweight and compact nature also contributes to robotic platforms’ overall agility and efficiency, enhancing their versatility and performance in various applications.

-

Automotive Electronics:

The automotive industry is increasingly adopting flexible PCBs to meet the growing demand for advanced electronics in modern vehicles. Flexible PCBs are used in a wide range of automotive applications, including infotainment systems, dashboard displays, advanced driver-assistance systems (ADAS), and powertrain control modules. The flexibility and compactness of flexible PCBs allow for efficient packaging and integration into tight spaces within the vehicle while also providing resistance to vibration, shock, and temperature extremes.

As automotive technology continues to evolve towards electrification, automation, and connectivity, flexible PCBs will play a crucial role in enabling the next generation of smart and sustainable vehicles.

Conclusion:

Flexible PCB manufacturing represents a paradigm shift in electronics design and assembly, offering unparalleled flexibility, durability, and versatility. By understanding the unique challenges and opportunities associated with flexible PCB fabrication, manufacturers can harness innovative practices to push the boundaries of what’s possible in electronic device design.

As technology continues to evolve, flexible electronics will undoubtedly play a pivotal role in shaping the future of electronic devices, driving innovation, and enabling new possibilities in various industries. With the emergence of cutting-edge techniques and materials, the journey toward flexible electronics promises to be an exciting and transformative one, paving the way for a new era of interconnected and adaptable devices.