Expert PCB Layout Services for Optimized Performance and Reliability

Transform your schematic into a manufacturable, high-performance PCB design with our expert layout services. We specialize in optimizing for signal integrity, EMI/EMC compliance, and manufacturability. (Explanatory, benefit-driven, and outlines core competencies)

Our PCB design and layout engineers are eager to collaborate with you, regardless of the size or complexity of your project. Whether your project requires high-speed constraint-driven requirements or basic I/O, our team has the knowledge to deliver a comprehensive design package that is complete, on time, and correct the first time. We provide two stages of design reviews: offline and interactive online.

We use Altium Designer, Cadence Orcad, Allegro, KiCAD, etc. for our PCB Design projects.

Why Work With Us

1. Cost and Efficiency:

- Implement lean manufacturing

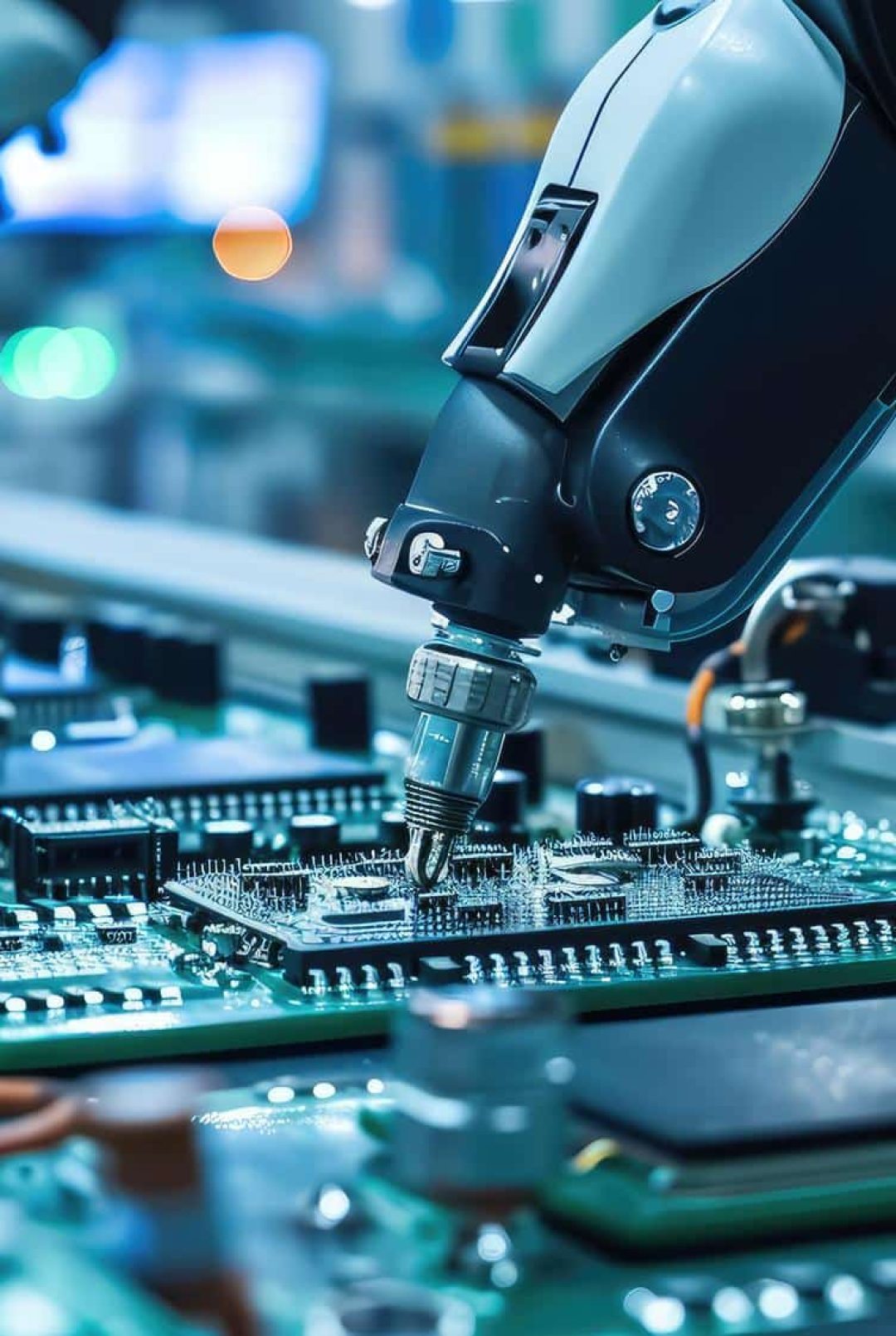

- Utilize advanced automation and robotics

- Offer value engineering

- Establish strategic partnerships with component suppliers

2. Time-to-Market:

- Adopt agile product development methodologies

- Offer rapid prototyping services

- Maintain close collaboration and communication with clients

- Leverage advanced manufacturing technologies

3. Complex Regulatory Compliance:

- Develop a deep understanding of relevant regulations and standards

- Establish robust quality management systems

- Employ certification experts

- Maintain thorough documentation and traceability

4. Intellectual Property Protection:

- Implement strict access controls, confidentiality agreements, and non-disclosure agreements (NDAs)

- Establish secure systems and protocols

- Clearly define and enforce IP protection policies

- Regularly update security measures

5. Supply Chain Management:

- Build strong relationships with trusted suppliers and distributors

- Conduct thorough supplier audits

- Implement supply chain visibility tools and processes

- Develop contingency plans and alternative sourcing strategies

6. Technological Advancements:

- Invest in continuous learning and development programs for employees

- Collaborate with technology partners and research institutions

- Foster an innovative culture within the organization

- Provide technology consulting services to clients

7. Skill Gap:

- Establish training and mentorship programs

- Collaborate with universities and educational institutions

- Engage in industry associations and participate in knowledge-sharing events

- Offer design and manufacturing consulting services to clients

8. Customization and Flexibility:

- Maintain a customer-centric approach

- Offer flexible manufacturing capabilities

- Develop modular design approaches and flexible manufacturing processes

- Foster strong communication channels with clients

Comprehensive PCB Layout Solutions

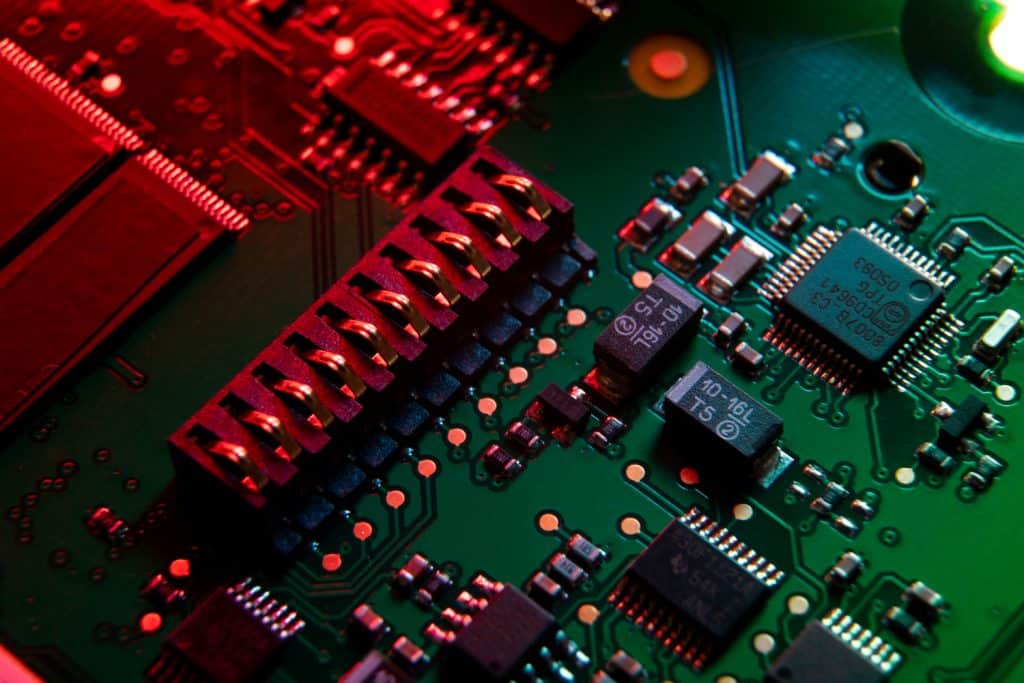

We offer various PCB layout services, from simple single-sided boards to complex multilayer designs. Our experienced engineers utilize industry-leading tools and best practices to ensure your design meets the highest standards. Our services include:

Schematic Review & Capture: We can review your existing PCB schematic design or create a new one based on your design specifications.

- Component Placement: Strategic component placement for optimal signal integrity, thermal management, and manufacturability.

- Routing & Signal Integrity Analysis: Precise routing and signal integrity analysis to minimize signal loss and ensure reliable performance.

- EMI/EMC Optimization: Design for electromagnetic compatibility to minimize interference and ensure compliance with regulatory standards.

- Thermal Management: Thermal analysis and design optimization to prevent overheating and ensure reliable operation.

- Design for Manufacturability (DFM) Analysis: DFM review to identify and address potential manufacturing issues early in the design process.

- Gerber File Generation: Generation of industry-standard Gerber files for PCB fabrication.

What do we need for design & layout?

- Schematics (suffixes . DSN and . SCH)

- DXF structural drawing (2D drawing in AutoCAD format)

- Component data sheet (must include component package footprint)

- Special requirements

Panelized Data:

- We will include panelization at no extra charge if your design can benefit from it.

- We include PCB fiducials.

- PCB rails with fiducials and tooling holes are added.

- X and Y array parameters can be specified.

- We can add mouse bites and/or V-Scoring if desired.

- The files for the panelized version are the same as those for the one-up design.

Liability:

- We have experienced layout designers on staff and are dedicated to providing excellent customer service. However, you are ultimately responsible for design functionality and manufacturability. We make no guarantees about the design of your PCB.

- Our liability shall not exceed the amount of the order placed.

- We make no other express or implied warranties and expressly disclaim all other warranties, including merchantability and fitness.

Experienced Engineers & Advanced Tools

Our team of highly skilled Printed Circuit Board layout engineers has extensive experience designing boards for various applications. We utilize industry-leading design software and tools to ensure the highest quality and accuracy. Our expertise includes:

- High-Speed Design: Expertise in designing high-speed PCBs with controlled impedance and optimized signal routing.

- RF Design: Specialized knowledge in designing RF PCBs with minimal signal loss and interference.

- Multilayer PCB Design: Experience in designing complex multilayer PCBs with blind and buried vias.

Capabilities and Services Offered:

- Schematic capture

- Board layout based on a schematic diagram supplied

- Custom footprint design

- Full BOMs and part pricing for each design

- Fabrication Drawing, assembly, and Gerber files are required to meet manufacturing specifications.

- Reverse engineering

- Designs with controlled impedance (single and differential)

- Designs for High-Speed Backplanes and Mid-Planes Blind & Buried Vias / Micro BGA / Micro Vias.

- Split ground planes, Differential pairs, Multi-layer boards and High-speed rules.

- Customer-specified routing per trace/space, keep-out, and clearance rules.

- DFT audit, test point placement, test probe clearance in accordance with customer requirements, testability report.

- Surface mount or through hole configurations.

- PCBs with unusual shapes.

Quality & Precision in Every Layout

We are committed to delivering high-quality PCB layout design services that meet your exact specifications. Our quality assurance process includes:

Design Reviews: Thorough design reviews at each stage of the process to ensure accuracy and completeness.

Signal Integrity Analysis: Comprehensive signal integrity analysis to verify performance and identify potential issues.

DFM Checks: Detailed DFM checks to ensure manufacturability and minimize production costs.

Efficient Design & Competitive Pricing

We offer competitive pricing and efficient custom PCB designing services processes to minimize lead times and meet your project deadlines. Request a quote today to get started.

Optimize Your PCB Design for Success with Our Expert Layout Services.

Frequently Asked Questions

We work with a wide range of clients, from start-ups to large corporations, across various industries. We have experience designing and manufacturing custom electronics for various applications, including IOT devices, industrial equipment, consumer electronics, and more. We can provide the support and guidance they need to bring their ideas to life. We understand the unique challenges our clients face. We can offer flexible payment options and tailored solutions.

We provide a wide range of product design and manufacturing services, including electronic product concept design, hardware circuit design, software development, PCB layout, exterior and interior structure design, prototype production, mass production, supplier management, procurement services, other specific services, and sales of some electronic products. Our goal is to provide a full range of customized solutions based on customer needs.

The cost of product development varies depending on several factors, such as the complexity of the design, the number of prototypes required, and the volume of production. Once we have a better understanding of your specific requirements, we will provide you with a detailed quote.

Our development process typically involves the following steps:

- Requirements gathering: We will work with you to gather your product requirements and develop a detailed product specification.

- Concept design: We will develop a concept design for your product, including schematics and PCB layout design services.

- Prototyping: We will build a prototype of your product to test its functionality and performance.

- Production: Once you are satisfied with the prototype, we will move into production and manufacture your product.

Our typical project timelines range from a few weeks to several months, depending on the complexity of the design and the number of prototypes required. We will provide you with a detailed project timeline once we have a better understanding of your specific requirements.

Yes, we provide after-sales support and maintenance services. Once your product is delivered, we will continue to work with you to provide the necessary technical support, troubleshooting, and maintenance services to ensure its normal operation and the satisfaction of your customers.

We provide complete documentation for our custom circuit board layout designs, including schematics, PCB layout files, and a bill of materials, production files etc.

Yes, we provide rapid prototyping services interms of bare PCB and PCB assembly.

Prototyping is an important step in the development process, as it allows you to test the functionality and performance of your product before moving into production.

Yes, we offer after-sales support and maintenance services. We are committed to providing our clients with the support they need to ensure the long-term success of their products.

Yes, we have a number of certifications and accreditations, including RoHS, ISO 9001, ISO 14001, and ISO 13485. These certifications demonstrate our commitment to quality, environmental sustainability, and medical device safety.

If you already have a schematic design, we can provide you with PC board layout services. We will work with you to ensure that the layout meets your design requirements and is manufacturable.

Yes, we can get started with printed circuit board layout before the schematics and BOM are completely finalized. However, it is important to note that changes to the schematics or BOM may require changes to the PCB layout,which results in a longer development time.

We use a variety of design tools for PC board layout, including Altium Designer, Cadence Allegro, EasyEDA etc.