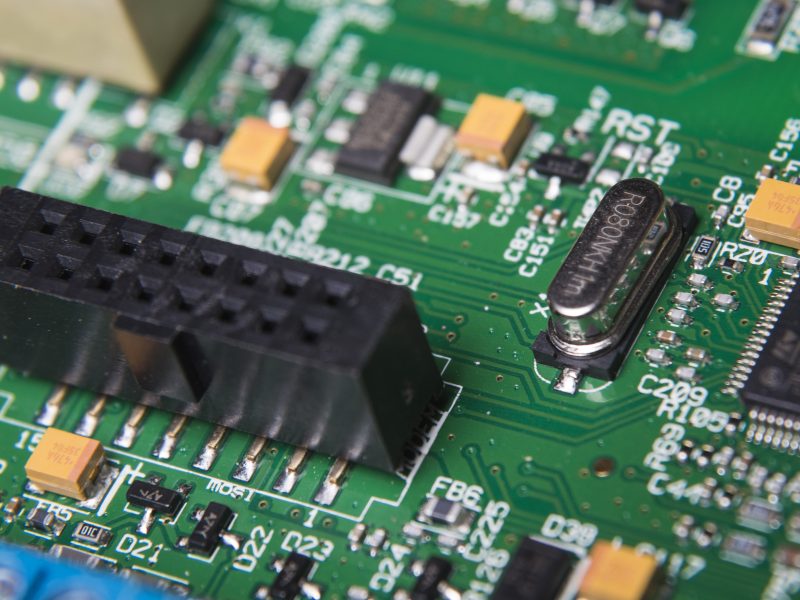

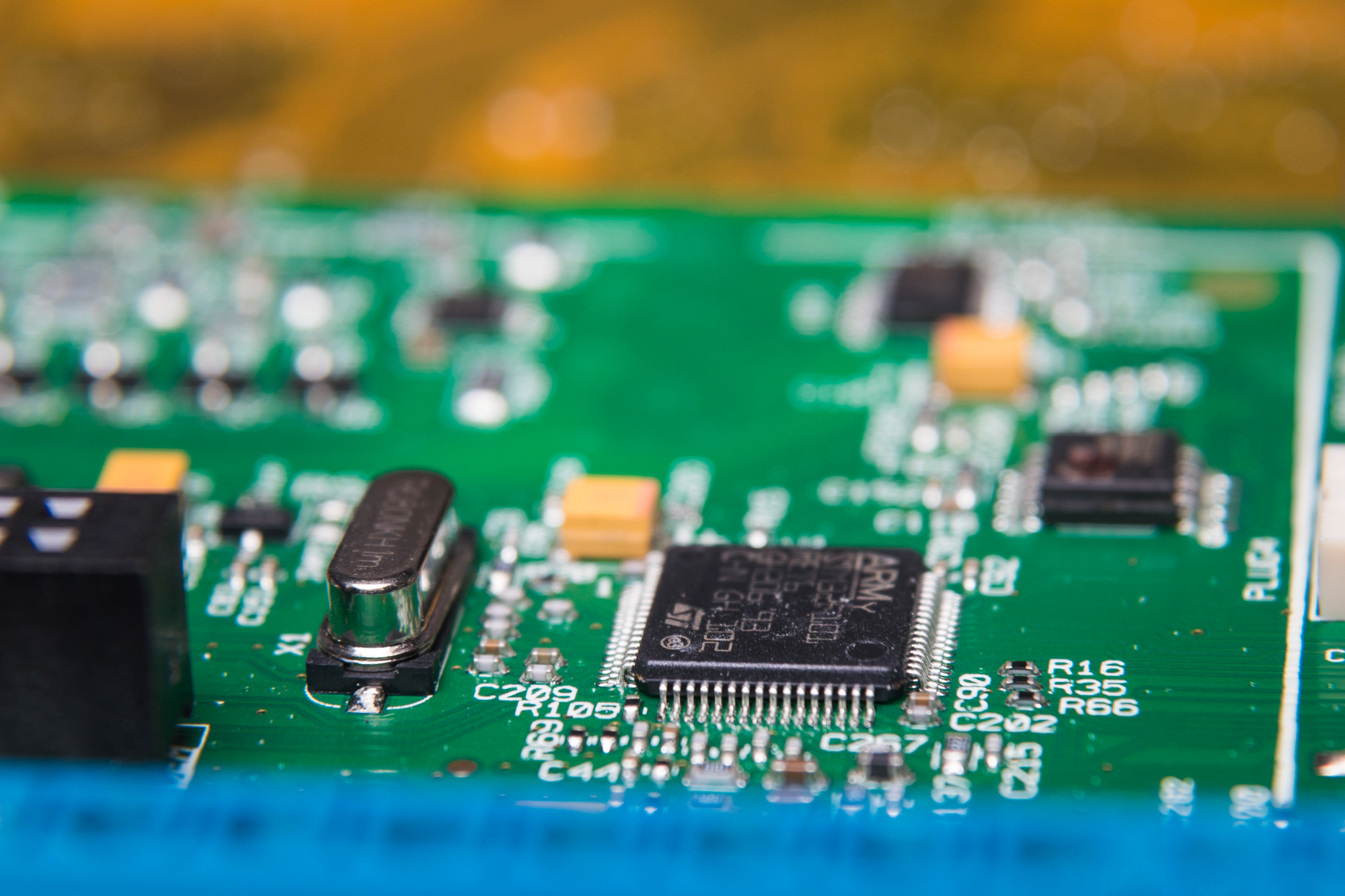

PCB, also known as Printer Circuit Board, has always remained the backbone of the electronics industry. It’s the sole source of electricity for various electronic equipment, such as washing machines, kitchen equipment, or technical machinery. In other words, the foundational power platform facilitates the flow of electricity to the range of electronic components that make the devices function.

Understanding PCB Manufacturing

PCB Manufacturing starts with the design phase, in which the PCB layout is decided. Then, it passes through the fabrication process, where different materials and components are embedded. In the final stage, the engineers ensure that the circuit’s components are correctly assembled and that there are pathways for electrical connections.

The Role Of Quality Assessment in PCB Manufacturing

An efficient quality assurance system must be imposed on the process to ensure that PCB manufacturing level meets high standards.

A study of 2022/2023 about workers in Great Britain found that nearly 135 workers lost their lives in work-related accidents, and the notable cause for this accident was contact with electricity. So, understanding the dangers of electrical components is a must, as these accidents might occur due to electrical errors or inadequate functioning of PCBs.

Quality checks help detect issues occurring in the construction process side by side and help the engineers make the required fixes. The stakes are high today when it comes to electricity accidents.

Therefore, it is essential to have strict quality controls while devising any PCB system.

Let’s have a look at how quality assurance upkeeps quality of PCB boards:

- Visual inspections are made at each stage to detect errors related to misaligned components, wrong soldering methods, and any internal faults committed.

- A post-assembly check is also conducted to ensure the PCB operates as intended.

- In the final stage, the PCB is evaluated to determine whether it meets all the operational standards. Then, the handlers are granted certification, confirming that the PCB is ready for installation.

Common Causes Of PCB Board Manufacturing Defects

Despite taking care of every aspect, there are still chances of some common errors creeping into the PCB building.

Let’s have a look at some of the causes of why defects occur in PCB manufacturing processes:

-

Improper Designing

Many errors occur in PCB buildings due to design issues. Sometimes, the traces have insufficient spacing, and annual rings are designed around drilled holes. Other reasons can be acid traps that damage electrostatic discharge. These design-caused effects lead to PCB malfunctioning.

-

Flawed Materials

Engineers using low-quality or flawed materials in PCB construction, like low-quality laminate foils, can cause incidents. Using below-par compositions in the designing phase can significantly impact PCB performances and sometimes lead to fatal events. Choose the best PCB board circuit manufacturer for your project to remain safe.

-

Inapt Thermal Management

Choose the best PCB board circuit manufacturer for your project to maintain safer thermal compressions. Inept and poor thermal management cause components to overheat. Poor thermal issues arise when insufficient attention is given to thermal components analysis, ultimately leading to PCB system failure.

-

Testing Errors ( Electrical & Design )

Another reason for discrepancies in PCBs is when testing is not done consciously. For example, the quality experts did not look for design violations, such as incorrect trace widths and improper component placement.

The design experts also neglected signal integrity and did not perform a needed thermal analysis. All these errors in the design and testing stages increase the chances of fatal consequences.

-

Soldering Defects

Soldering is crucial in the assembling phase. This step ensures electrical connectivity and mechanical stability. Sometimes, issues like cold solder joints and improper solder paste application creep up, disturbing the functioning of PCB systems.

-

Mechanical Harm

PCBs are thin and delicate components that are easily susceptible to damage during the fabrication process. Scratches, impacts, and dents harm the overall construction of boards. This interferes with PCB functionality, which lowers electricity performance.

-

Inconsistent Layer Density

Inconsistent layer density refers to the density of copper and other conductive materials used in PCB design. The wrong and inadequate use of conducive components in PCBs can significantly impact PCB systems’ performance, reliability, and functionality.

Escalating PCB Manufacturing Level: Strategic Approaches To Enhance PCB Board Design

PCB manufacturing is a process that needs adept precision with attention to minor details. Let’s watch out which strategic approaches or essential techniques PCB builders should follow for desired outcomes:

-

Automated Optical Inspection

Automated Optical Inspection is an advanced technology that generates PCB defects early in production. It’s a machine-powered system to assess any violations made in PCB design, fabrication, and assembly stages. High-resolution cameras capture detailed PCB images and provide operators with real-time feedback.

-

Design For Manufacturing ( DFM Principles )

It means setting up the design principles to wash out the chances of errors and cost insufficiencies. It includes working on complex geometries of PCBs, layering, component placement, and material selection to final assembly.

-

Electrical Testing

Electrical testing helps identify unintended connections or broken or incomplete circuits in manufacturing. Component integrity is also assessed to ensure that the parts of PCBs are aligned correctly.

-

Statistical Process Control

Statistical Process Control is also one of the best methodologies for assessing the quality of PCBs at each stage. This step checks the quantity and quality of materials and examines each product’s minute details, ensuring no errors arrive at different PCB building stages.

-

Supply Chain Quality Check

The supply chain check ensures that PCB meets specific quality standards. This process thoroughly vets and audits suppliers’ material quality and minimizes the risk of receiving defective materials that can cause delays or failures in PCB functionality.

-

Thermal Inspection

It is imperative to check thermal management for PCBs. Inapt installation of thermal systems in the PCB leads to overheating of electrical equipment. Proper thermal inspections can nullify the chances of degradation of components, including solder joints, copper layerings, and even the PCB substrate.

How does PCBLOOP Help upgrade the quality of PCB Board Design?

PCBLOOP is the leading electronics manufacturer in China that specialises in Printed Circuit Boards. The company is dedicated to offering a combination of electronic manufacturing services that run on advanced technologies and are designed with rigorous quality control techniques.

Here’s how PCBLOOP helps in upgrading PCB board design; let’s have a look:

-

Advanced Manufacturing Processes

PCBLOOP experts work with great precision. The AOI (Automated Optical Inspection) system recognizes production defects in real-time and allows immediate corrections, ensuring that PCBs are free from visual and structural defects.

-

Comprehensive Quality Control

The engineers work under a comprehensive quality control system. PCBLOOP carefully examines if the raw materials or other components are ideal for use in the construction process. Before using them for PCB design, they also test the material’s durability, endurance, and stability.

-

Innovative Design Solutions

Design for Manufacturing (DFM) concepts are used in creating PCBs to ensure they follow current trends. The focus is more on innovative applications in PCB Manufacturing for better functionality. Furthermore, DFM systems guarantee that the appropriate and superior materials can be used to create PCBs.

The Bottom Line

PCBs are crucial systems deployed in various locations, including malls, business buildings, and houses. Perfect construction is required to guarantee that these work safely. You must hire PCB manufacturing experts who work with adept care. Quality control checks must be incorporated into PCB constructions to ensure that no deadly consequences occur in the future.