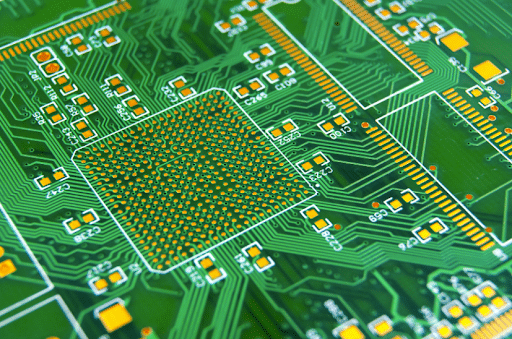

Printed Circuit Boards (PCBs) are the backbone of countless devices we use daily. From smartphones to industrial machinery, PCBs are the essential electrical connection conduit. However, the efficiency and reliability of these devices heavily rely on the high quality of PCB manufacturing.

Quality Assurance (QA) is not just a step in the process; it’s a commitment to excellence that permeates every aspect of production. In this blog, we’ll delve into the pivotal role of QA in PCB manufacturing, exploring the top nine secrets that ensure the production of high-quality PCBs. From circuit board design optimization to team collaboration, each element plays a crucial role in achieving excellence in PCB manufacturing.

Understanding the Importance of Quality Assurance

Quality assurance in PCB manufacturing is not merely a checkbox; it’s a fundamental principle that underpins the entire process. Ensuring high-quality PCBs enhances product reliability and reduces the likelihood of costly recalls and repairs, safeguarding reputation and revenue.

A robust QA system encompasses stringent standards, meticulous testing, and proactive problem-solving. It involves every manufacturing stage, from PCB layout design to final inspection, fostering a culture of excellence and accountability.

Top 9 Secrets of Manufacturing High-quality PCBs

1. Understanding Design Optimization and DFM

The journey towards high-quality PCBs begins with meticulous PCB layout design. Design for Manufacturability (DFM) principles should be integrated to streamline the manufacturing process and minimize potential errors.

This involves optimizing component placement, trace routing, and ensuring adequate clearance and spacing. PCB layouting is not just about arranging components. It is about creating an efficient, manufacturable design that maximizes performance and reliability.

Talking about trace routing is crucial in optimizing the PCB layout. Efficient routing involves establishing clear pathways for electrical signals while minimizing signal interference and ensuring signal integrity. Careful attention to routing can help reduce signal delays, improve signal Quality Assurance, and enhance overall system performance.

2. Choosing the Right Supplier

Selecting a reliable PCB manufacturer is paramount. Look for suppliers with a proven track record of quality and reliability. Consider factors such as manufacturing capabilities, adherence to industry standards, and customer feedback. Collaborating with a trusted partner ensures consistency and excellence in every batch of PCBs.

A reliable supplier is not just a vendor but a strategic partner invested in your success. Other than PCB suppliers, components suppliers are crucial to the PCB assembly product’s final Quality Assurance .

Pay close attention to customer feedback and reviews when evaluating potential suppliers. Insights from other clients can provide valuable insights into the supplier’s reliability, responsiveness, and overall customer satisfaction.

Look for testimonials and case studies highlighting the supplier’s ability to meet deadlines, promptly address concerns, and maintain open communication throughout manufacturing.

3. Component Placement and Ideal Alignment

Component placement and ideal alignment are not merely procedural steps in the manufacturing process; they are foundational pillars upon which the entire functionality and reliability of electronic systems rest. This critical aspect of engineering demands meticulous attention to detail and an understanding of the intricate interplay between components.

In the realm of PCB layout design, achieving precise component placement stands as a linchpin for optimal performance and unwavering reliability. It’s akin to orchestrating a symphony, where each instrument must be positioned with precision to harmonize seamlessly and produce a flawless melody. Similarly, in electronics, every component must find its rightful place on the PCB (Printed Circuit Board) design to ensure smooth operation and efficient functionality.

4. Keep Soldering Temperature and Time in Check

Soldering is a critical process that demands precision and control. Maintaining the correct soldering temperature and duration is essential to prevent defects such as cold joints, solder bridges, and component damage. Employing advanced soldering techniques and monitoring equipment ensures uniform soldering and adherence to quality standards.

Advanced soldering techniques, such as the use of soldering irons with precise temperature control or reflow ovens for surface-mount components, provide the necessary precision to meet stringent quality standards.

Additionally, employing monitoring equipment, such as thermocouples or infrared cameras, allows real-time monitoring of soldering temperatures, enabling prompt adjustments to ensure optimal conditions throughout the process.

5. Use Premium Quality Flux

Flux plays a vital role in soldering by promoting wetting and preventing oxidation. Opt for high-quality flux compatible with the soldering process and materials used. Quality flux enhances solderability, improves joint strength, and reduces the risk of defects such as voids and cracks. Investing in premium flux is not just a cost; but also an investment in the reliability and longevity of your PCBs.

By prioritizing quality over cost-cutting measures, manufacturers can mitigate the risk of solder-related defects and ensure the consistent performance of their electronic devices. In the long run, the benefits of using premium flux far outweigh the initial investment, leading to enhanced product reliability, reduced rework, and, ultimately, greater customer satisfaction.

6. Use Proper ESD Protection

Electrostatic discharge (ESD) poses a significant threat to PCBs during manufacturing and assembly. Implement proper ESD protection measures to safeguard sensitive components and circuits from damage. This includes using antistatic workstations, grounding straps, and ESD-safe packaging throughout production.

ESD-safe packaging is essential for transporting and storing sensitive electronic components and PCBs. ESD-safe packaging materials, such as conductive foam and static-shielding bags, protect against external static charges and prevent damage during transit and storage.

7. Perform Inspection Processes

Regular inspection is a cornerstone of quality assurance in PCB manufacturing. Conduct thorough visual inspections, automated testing, and functional testing at every stage of production. Identify and rectify any anomalies or defects promptly to maintain the highest standards of quality and reliability.

Manufacturers can identify and rectify defects early by performing comprehensive inspection processes throughout the production cycle, minimizing the risk of defective products reaching the market. This proactive approach enhances product Quality Assurance and reliability, reduces rework costs, and improves overall manufacturing efficiency.

8. Focus on Team Collaboration

Effective collaboration among stakeholders is key to achieving excellence in PCB manufacturing. Foster open communication and teamwork between design engineers, production staff, and quality control personnel. Encourage knowledge sharing, feedback loops, and continuous improvement initiatives to optimize processes and enhance product quality. Qualified workers operate and implement as per the SOP(Standard Operation Procedure), which also plays a crucial role in the final product quality.

9. Tracking and Analysing Data

Data-driven insights are invaluable for continuous improvement and quality optimization. Implement robust data tracking and analysis systems to monitor key metrics such as defect rates, yield rates, and process efficiency.

Use this data to identify trends, diagnose issues, and implement corrective actions that drive quality and productivity improvements. Data analysis is about crunching numbers and gaining actionable insights that inform decision-making and empower your team to deliver exceptional results.

Final Thoughts

The quest for high-quality PCBs is an ongoing journey fueled by innovation, collaboration, and a relentless pursuit of excellence. By embracing the secrets of manufacturing outlined above and prioritizing quality assurance at every step, manufacturers can deliver PCBs that meet the highest standards of performance, reliability, and customer satisfaction.

Quality is not just a metric. It’s a mindset—a commitment to craftsmanship and integrity that defines the very essence of PCB manufacturing.

PCBLOOP aspires to continue raising the bar, upholding the principles of excellence, and propel the industry forward into a future where high-quality Quality Assurance PCBs power innovation and inspire confidence in every device they inhabit.