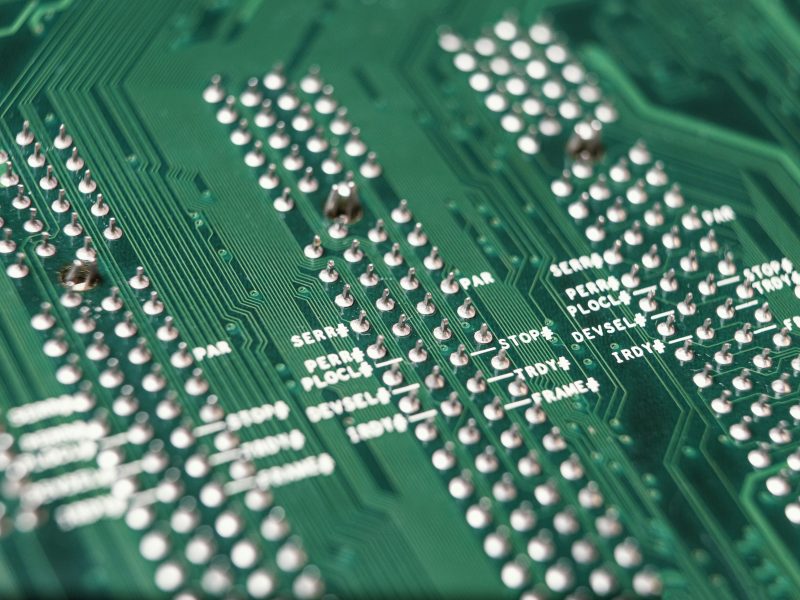

Printed circuit boards (PCBs) are fundamental components that serve as the backbone for electronic devices. The quality and performance of a PCB can significantly impact the overall functionality of the final product. Therefore, selecting and evaluating the right PCB supplier is a critical decision for any business involved in electronics manufacturing.

This blog will delve into the importance of choosing the right PCB supplier, provide a comprehensive guide on picking the right one, and highlight essential criteria for evaluating potential partners.

Significance of Choosing the Right PCB Supplier for Business Success

The choice of a PCB board manufacturer is pivotal for the success of an electronics manufacturing business. A reliable PCB supplier ensures high-quality products, timely deliveries, and competitive pricing, which are crucial for maintaining production schedules and meeting market demands. A good supplier can also provide valuable technical support, helping businesses overcome design and manufacturing challenges.

A poor choice can lead to delays, increased costs, and product failures, ultimately harming the business’s reputation and bottom line. So, it is important to conduct a thorough audit of a PCB supplier before selecting one for your needs.

How to Pick the Right PCB Supplier?

There are factors to consider before picking up the right PCB supplier.

Some of the crucial ones are:

-

Understanding Your Needs

Defining Your Requirements

The first step in selecting a PCB supplier is clearly defining your requirements. This involves understanding the specifications and standards your products must meet. Consider factors such as the type of PCBs needed (e.g., single-sided, double-sided, multi-layer), material specifications, design complexity, and any industry-specific standards that must be adhered to.

Clearly defined requirements will guide your search and ensure that potential PCB manufacturing companies can meet your needs.

Budget and Cost Considerations

Budget is another critical factor when selecting a PCB supplier. It’s essential to determine your budget constraints and understand the cost structure of potential suppliers. While cost should not be the only consideration, ensuring that the supplier’s pricing aligns with your budget without compromising quality is vital. Evaluate the cost-effectiveness of different suppliers by considering the total cost of ownership, including production costs, shipping, and any additional services provided.

-

Researching Potential Suppliers

Identifying Potential Suppliers

Once you clearly understand your needs and budget, the next step is to identify potential PCB board manufacturers. This can be done through various methods, including online searches, industry directories, trade shows, and referrals from industry peers.

Create a list of potential suppliers who meet your initial criteria and have a good reputation in the industry.

Gathering Information

Gather detailed information about each potential supplier. This includes reviewing their websites, requesting brochures, and understanding their capabilities and offerings. Pay attention to their years of experience and the industries they serve. Check if they offer innovative applications in PCB manufacturing and any certifications or quality standards they adhere to.

Look for customer reviews and testimonials to gauge their reliability and satisfaction levels.

-

Supplier Evaluation Criteria

Quality and Reliability

Quality and reliability are paramount when selecting a PCB supplier. Ensure the supplier meets international quality standards such as ISO 9001 and IPC-A-600 for PCB manufacturing. Request samples to evaluate the quality of their products and verify their reliability through references and case studies.

A supplier’s ability to consistently deliver high-quality PCBs will directly impact the performance and durability of your end products.

Manufacturing Capabilities

Assess potential suppliers’ manufacturing capabilities to ensure they can meet your production requirements. This includes evaluating their production capacity, technological capabilities, and the range of services they offer. Suppliers with advanced manufacturing technologies and flexible production capabilities are better equipped to handle complex designs and large-scale production needs.

Lead Time and Delivery

Timely delivery is crucial to maintaining production schedules and meeting market demands. Evaluate the lead times offered by potential suppliers and their ability to meet deadlines consistently.

Consider their location, shipping methods, and potential logistical challenges affecting delivery times. A reliable supplier should have a proven track record of on-time deliveries and efficient logistics management.

Cost and Pricing Structure

While cost should not be the sole determining factor, evaluating potential suppliers’ pricing structure is essential. Compare quotes from pcb board manufacturers to understand the market rates and ensure you are getting competitive pricing.

Consider additional costs, such as tooling, shipping, and handling fees.

A transparent pricing structure and clear communication about costs will help avoid any unexpected expenses down the line.

Communication and Support

Effective communication and support are critical for a successful partnership with a PCB supplier. Evaluate the responsiveness and professionalism of potential suppliers in their communication. Ensure they provide excellent customer support and technical assistance and are willing to collaborate closely to address any issues or challenges that may arise.

A PCB manufacturing company that is proactive in communication and offers robust support will be a valuable partner in your manufacturing process.

-

Building Long-term Relationships

Establishing Clear Agreements

Establishing clear agreements and contracts with your chosen PCB supplier is essential for a successful long-term partnership. Define all terms and conditions, including pricing, delivery schedules, quality standards, and dispute resolution mechanisms.

Clear agreements help set expectations and provide a framework for resolving any issues arising during the collaboration.

Continuous Monitoring and Evaluation

Once you have determined how to choose a PCB Circuit board manufacturer for your project, continuous monitoring and evaluation are crucial to ensure ongoing quality and performance. Regularly review the supplier’s performance against the agreed-upon criteria and provide feedback. Conduct periodic audits and inspections to verify compliance with quality standards and address any areas for improvement.

Maintaining an open line of communication and fostering a collaborative relationship will help address issues promptly and ensure a successful partnership.

Final Thoughts

Selecting and evaluating the right PCB supplier is a critical process that requires careful consideration and thorough research. By understanding your needs, researching potential suppliers, and evaluating them based on key criteria, you can find a reliable partner who will contribute to your business’s success.

Building long-term relationships with your PCB suppliers through clear agreements and continuous evaluation will ensure consistent quality, timely deliveries, and overall business growth.

With the right PCB board manufacturer, such as PCBLOOP, you can confidently navigate the challenges of PCB manufacturing and deliver high-quality electronic products to the market.