The only way businesses grow is through delegation. This can take the form of internal delegation, where you hire new employees to take on recurring, well-defined tasks. This can also take the form of outsourcing, where an outside contractor or firm is hired to compliment your current staff. The benefits and risks of outsourcing need to be considered in any business, and PCB layout outsourcing is no different.

If you’re an engineering manager at a design firm, or you’re a manufacturer looking for design support, you’ll need to weigh the pros and cons of working with an outside firm. If you understand the risks and benefits involved in working with a PCB layout outsourcing firm, you can provide better management for your projects and ultimately produce a higher-quality design. Take a look at the points we’ve compiled below before you select your next outsourced PCB layout firm.

You may like : The Best High Speed Board Design Guidelines

PCB Layout Outsourcing: Benefits and Risks

Obviously, there are some advantages and disadvantages to outsourcing your PCB layout work to an external firm. The benefits and risks shown below apply to almost any other task that needs to be outsourced. There is always the potential for low quality work, late delivery of finished designs, and being nickel-and-dimed for each task when you go the route of PCB layout outsourcing. When you’re deciding which firm to employ to help you meet deadlines for advanced designs, consider the following benefits and risks of PCB layout outsourcing.

Benefit: Access to more advanced design capabilities.

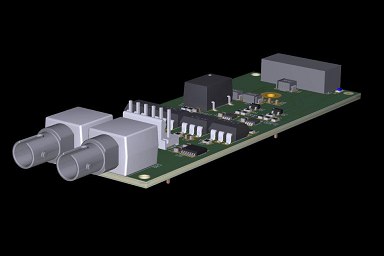

Your team may not have the expertise to work in a new area, but you might have deadlines you need to meet on lucrative projects. PCB layout outsourcing gives you access to a team with a broader skill-sets, and without having to hire new full-time employees. Your current team can focus on serving your existing customers, rather than slowly working through a design in an unfamiliar area. Some advanced areas, like microwave/mmWave design or electro-optics, are highly specialized and are not part of most designers’ repertoire. It doesn’t hurt to seek design or layout assistance from an external firm that specializes in these areas. Whenever we work on these kinds of advanced designs, we prefer to use cutting-edge collaboration tools to share data with clients.

Benefit: Costs can become more predictable.

If your PCB outsourcing strategy is executed correctly, you’ll be offloading some of the financial risk onto a 3rd party, especially when your PCB layout outsourcing firm quotes you at a fixed price. You’ll obviously pay a small premium for the two advantages listed above, but this can allow you to switch your cost basis from hourly to fixed-price in some cases. This requires working with a design firm that quote by time and materials, or on a fixed price basis.

Benefit: Access to outside talent helps you meet deadlines.

Everyone has deadlines they need to meet, and working with a PCB layout outsourcing firm gives you the temporary staff augmentation you need to get jobs done quickly. A design firm with access to a broad range of talent can help you get your designs finished quickly while also giving you access to talent beyond your current team’s experience.

Risk: Meeting DFM requirements.

If you go the route of a freelancer, there is a chance you are selecting a contractor that has never sent a board off to an advanced manufacturing facility. Similarly, some design firms may make assumptions on manufacturing requirements without asking. One way to avoid this risk is to choose a PCB layout outsourcing firm that has relationships with manufacturers. This unique type of firm will have the experience required to help you take a new design into manufacturing and will understand which questions to ask to ensure you comply with industry standards and DFM requirements.

A design team with deep experience using the best design packages will know how to quickly spot DFM violations in a layout.

Risk: Difficulty in collaborating and communicating.

Some PCB layout firms still resort to email for communication and delivery of finished design files. There is no single mode of communication that is the best choice during PCB layout outsourcing; it’s up to you to decide which method is best for your team. Whichever method you use for daily or weekly communication, your PCB layout outsourcing firm should be willing to adapt to your preferred communication method.

Read Also: Designing Your RF PCB stack-up

Communication is a two-way street; you’ll be able to quickly get your product to manufacturing and ensure your product is of the highest quality when you take the lead in engaging your outsourcing firm. Any time component or customer requirements changes arise, you need to take the initiative in communicating this information to your outsourced PCB layout firm. When you work with a PCB layout firm that uses the newest cloud collaboration tools, such as Altium Concord Pro, you’ll be able to easily provide information updates and reduce your risk.

Risk: You risk losing control over quality.

This is a fair point as different design firms carry different levels of expertise. The team lead at your PCB layout outsourcing firm needs to have significant experience vetting finished designs, ensuring manufacturability, and motivating a team to produce at their best. When you implement the best practices and tools for collaboration, you can ensure your design firm fully understands your needs and you can take a lead role in directing the progress of a design. This gives you a say in the final quality of the product and helps you spot problems before they become major obstacles to success.

If you keep these benefits and risks in mind, you can get to market quickly without compromising quality. The best PCB layout outsourcing services know the value of collaboration, how to accurately quote layout work, and maintain relationships with manufacturers. Whether you’re a larger design firm or a manufacturer yourself, you can expand your reach into a broader range of products when your partner with the right PCB design and layout firm.

PCB layout outsourcing can carry some risks, but the PCB design team at PCBLOOP has experience working on a range of advanced outsourced projects. We use the industry’s best PCB design software and the latest collaboration tools, which ensures your team is kept up to date on progress for your advanced designs. We are not only PCB layout outsourcing firm but PCBA manufacturer and we can ensure your board will be fully manufacturable at scale. We also provide embedded systems design services for advanced IoT products, industrial products, wearables, and much more. Contact PCBLOOP for a consultation.