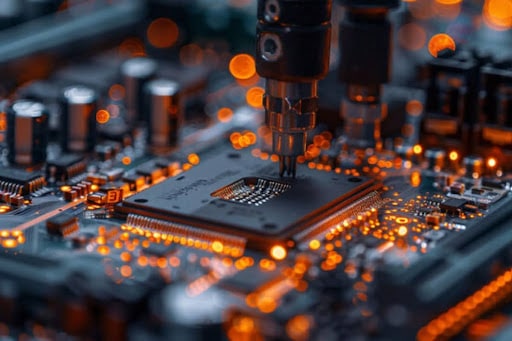

Does your PCB (printed circuit board) project always work? Do you find it annoying when your PCB stops functioning for no concrete reason—perhaps a short circuit? However, why does a short circuit happen?

Perhaps too much solder. Don’t worry, though; even skilled engineers have difficulties when soldering. So, if you have been looking for solutions to the different problems caused by soldering, then we have got you covered.

Here, you will learn about the world of PCB welding and explore different processes, techniques, and considerations for achieving exceptional PCB manufacturing.

Types of PCB Welding Processes

1. Manual Soldering Process

One of the oldest and most used methods for PCB welding is manual soldering, sometimes referred to as traditional welding. In this method, electronic components are connected to the PCB manually using iron heat and solder.

The following are some of the primary characteristics of the manual welding process:

- High Flexibility: Manual welding is a good tool for small batch and sample manufacturing, and it may be readily tweaked and changed as needed.

- Relatively low technical requirements: Compared to other advanced welding techniques, manual welding requires very little technical expertise from operators, and even non-experts can execute basic welding tasks.

- Lower cost: Manual welding is quite minimal in cost. It requires only basic tools to operate and does not require expensive mechanized equipment.

2. Wave Soldering Process

Wave soldering is a high-speed, automated technique for mass-producing PCBs. The PCB is transported by a conveyor belt through a wave of molten solder created by a constantly melting solder strip.

Due to surface tension and heat, the solder “wets” component leads as the PCB crosses the crest, forming trustworthy electrical connections. This method is perfect for large-scale electronics manufacturing since it is highly efficient and maintains a constant quality for several component pins simultaneously.

3. Surface Mount Technology (SMT)

Through-hole soldering was superseded by Surface Mount Technology (SMT), which allowed circuit board components to be mounted directly onto the board’s surface, completely transforming printed circuit board assembly. This approach has several benefits:

- Miniaturization: Because SMT components are much smaller, denser designs and more compact, tiny electronic devices are made possible.

- High-Frequency Performance: SMTs have shorter lead lengths, which reduce capacitance and inductance and make them perfect for high-frequency applications like computers and communication devices.

- Automated Production: SMT is ideal for high-volume production and increases overall efficiency since it uses automated equipment to solder components quickly, precisely, and consistently.

4. Reflection Welding Process

With the help of mirrors and heat reflection plates, reflection welding provides a special method for PCBs. This results in numerous significant advantages:

- Component Protection: In order to protect delicate electronic components like LEDs and photosensitive components, the brief contact time between components and the PCB reduces heat and electrostatic impact.

- High Speed and Efficiency: Reflection welding increases production efficiency and process control stability by using pulsed heat to weld faster.

- Precise Control: This technology provides accurate control over the heating process for components that are sensitive to temperature and may be harmed by conventional high-heat welding methods.

5. Lead-free Soldering Process

A soldering technique called lead-free soldering was developed to satisfy environmental protection regulations. Lead-free soldering procedures are gradually replacing traditional lead-containing soldering techniques because lead-containing solders may present possible hazards to human health and the environment.

These are some of its primary attributes:

- Environmental Protection: Lead-free solder is used in the lead-free soldering process to lower operator health hazards, comply with environmental protection regulations, and lessen environmental pollution.

- Stable Welding Quality: Lead-free solder has good wettability and reliability, which helps achieve welding quality comparable to traditional lead-containing soldering.

- High Surface Tension Control Requirements: Lead-free solder has a rather high surface tension; therefore, careful control over the welding procedure and conditions is necessary to guarantee both the weld’s quality and the connection’s dependability.

6. Reflow Soldering

Reflow soldering, also known as hot plate soldering, utilizes a highly automated approach for mass-producing PCBs.

Here’s what makes it stand out:

- Automation Advantage: Reflow soldering depends on automated machinery, which ensures a precise and effective welding procedure for reliable outcomes.

- High-Volume Production: This approach greatly benefits large-scale PCB production. It makes batch processing effective and raises production output overall.

- Precise Temperature Control: Hot plate welding necessitates exact temperature management to guarantee that the welding process’s temperature curve satisfies specifications and prevents component damage.

7. Vapor Phase Relative Welding Process

Vapor phase soldering (VPS) offers a unique printed circuit board assembly approach. The board is immersed in a special liquid with a high boiling point. This liquid vaporizes within the chamber, creating a saturated environment with exceptional temperature uniformity, which translates to several key benefits.

Firstly, even heat distribution across the entire PCB minimizes thermal imbalances and prevents defects commonly seen in other soldering methods. Secondly, VPS often utilizes environmentally friendly liquids as the heat transfer medium, reducing health risks and adhering to stricter environmental regulations.

Finally, the process excels at handling complex PCBs with intricate structures and densely packed components, ensuring high-quality and reliable solder connections. These advantages make VPS a compelling option for specific PCB applications.

How to Choose the Right Welding Process for PCB?

- Product Requirement: Choose a welding technique that can satisfy the requirements based on the product’s structural features, performance requirements, and usage environment.

- Production Scale: Based on the production batch’s size and the production cycle’s needs, choose a suitable automated welding procedure to increase production efficiency.

- Cost Control: When choosing an affordable and sensible welding procedure, consider the cost of the equipment, the materials, the personnel, and other aspects. You can even learn about better ways to control costs in a cost-effective pcb manufacturing guide.

- Process Control Requirements: The viability and stability of process control must be guaranteed, as various welding processes have varying demands on ambient factors and process parameters.

PCB Welding Techniques

The PCB manufacturing world utilizes a diverse range of soldering techniques, each with its advantages and limitations. Here’s a closer look at some of the most common methods:

- Hand Soldering

With this traditional technique, solder is precisely heated and applied using a portable soldering iron. Because of its versatility, hand soldering is great for prototypes, small-batch manufacturing, and rework, but it takes a high level of operator skill to guarantee reliable, high-quality output.

- Selective Soldering

Selective soldering uses a robotic arm with a soldering iron tip, providing more control and flexibility than wave soldering. This focused method works well for complex boards with components of different sizes since it enables exact solder application on selected points.

Considerations for Exceptional Soldering

Excellent PCB soldering is influenced by several criteria in addition to selecting the appropriate technique. You need to look for the key requirements for PCB Manufacturing and some other considerations, which are-

- Solder Selection

The proper solder alloy with the correct melting point and composition must be chosen for the best joint formation and performance.

- Soldering Iron Tips

Using the soldering iron with the appropriate tip size and material ensures proper heat transfer and effective solder application.

- Process Control

Reliability and repeatability in solder junctions are contingent upon the maintenance of accurate temperature profiles and consistent application processes.

- Inspection and Rework

It is essential to establish a thorough inspection procedure to find and fix flaws, including excessive solder, bridges, and dry joints. Precisely established rework protocols guarantee prompt rectification of any soldering mistakes.

Conclusion

The key to excellent PCB manufacturing is choosing the best welding procedure for your project’s requirements. By knowing the advantages and disadvantages of several processes, such as hand soldering, wave soldering, and reflow soldering, manufacturers can guarantee excellent connections, effective production, and compliance with environmental standards.

Remember, the art of soldering goes beyond the equipment—meticulous process control and skilled personnel are key to creating reliable and functional PCBs.